- Materials - Tools - Components >

- Lubrication >

- Lubrication unit

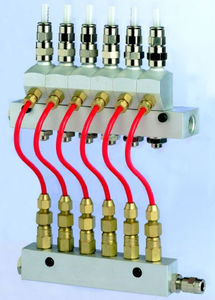

Lubrication units

Ideal for single or combined relubrication of: roller bearing racks / open gears linear guides ball swivel connector ball screw

... mechanics make it possible. The application of the lubricant to, for example, a conveyor chain takes place, as in the case of known oildrippers, via a lubricating brush of the appropriate width or ...

Schmiertechnikwerk - STW

... forward in lubricant delivery Minimum Quantity Lubrication (MQL) replaces the flood coolant commonly used in machining with a minute amount of high-quality lubricant precisely applied ...

Unist, Inc.

A minimal lubrication system operating on ultra low oil consumption. Compressed air is used as a carrier. Metered oil, suitably mixed with air, is conveyed in non atomised state to the lubrication ...

Tension springs press the lubricating rollers onto the coil material. The contact between the low-wear felt rollers and the coil material allows the forming lubricant to be applied oil mist-free. The ...

RAZIOL

The Micro lubrication system was developed for the outside lubrication of machining and forming tools. Reproducible setting of the spray volume, robust construction of the pump (stainless ...

Air Operated Greasing Kit - 20kg Technical Specifications 50:1 ratio grease pump Flow rate: 1.1kg/min Suitable for use with 20 to 30kg grease drums, depending on dimensions Air inlet 1/4" F / Pump outlet 1/4" F Min/max ...

Macnaught Pty Ltd

... . Why choose the MVJ-1 Modular Minimum Quantity Lubrication System? Precision Lubrication: Say goodbye to wasteful lubricant overuse. The MVJ-1 ensures that only the required amount ...

... -substance nozzle. This eliminates the use of cost-intensive compressed air at the nozzles, which is used in conventional units and causes spray mist.

... Individually controlled airflow valve, lubricant control, and frequency generator for maximum output control Co-axial hose assembly atomizes the lubricant at the nozzle tip for consistent application ...

Accu-Lube (ITW)

... complement press speeds up to 300 FPM. STOCKLUBE SYSTEM FEATURES The systems consist of a lubricating head assembly and a pump and tank unit. Lubricating heads are available in three ...

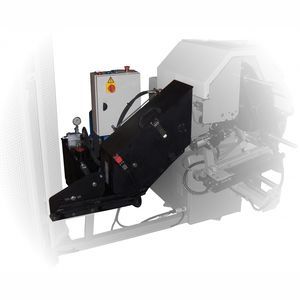

... central lubrication unit consists of an electric pump, butterfly valve, and storage tank. The pump is designed for single-line operation; multiple pumps (multi-line operation) can easily be attached if ...

Murtfeldt

80791 Greasing kit for 180/200kg drums, composed of: - Pneumatic pump mod. 81880 - Automatic hose reel mod. 37115 - 15m of 1/4” rubber hose, mod. 81015 - Drum cover diam. 600 mm, mod. 80580 - 3m of 1/4” rubber hose, ...

Ompi Srl

Targeted lubrication of metal coils and blanks We offer felt roller lubricators in a variety of different model ranges. The rollers are generally driven by the feed machine, but we also offer systems equipped with their ...

Eckardt Umformtechnik GmbH Systeme für die Umformtechnik

... location-based dispensing of flange lubrication. Its intelligent design senses the location and intensity of track curves using a combination of GPS signals, speed and inertial sensors. The unit processes ...

This high-performing machine electronically controls the two axes and performs a deep lubrication, particularly of the mold’s inner walls thanks to specially designed hollow cone spraying heads. It is especially suitable ...

Die Lubrication Solutions Srl

... pump actuation. Greasing valve lever engagement starts the grease promotion, its disengagement ends the grease flow, finishes the lubrication process respectively. The mobile MATO eHybrid-Greaser ...

Mist lubrication system for Model 3A and 6A Cut-Off Machines - Near-dry mist lube unit sprays minute quantities of lubrication on the cut-off blade to improve blade ...

... adequate lubrication is needed. Manual lubrication is often unreliable and very costly. Lubrication system, developed by ATLANTA for rack and pinion drives, is based on the grease gun ...

ATLANTA

... :1 is reliable even while lubricating at high pressure. This system is right for the job and solidly made for the maintenance of machinery and all mechanical equipment. This Grease Supply System guarantees reliable lubrication ...

... pump If the lubricating box’s cover is opened, the safety micro-switch, stops the coil winder and lubrication pump Wire motion sensor automatically starts and stops lubrication power ...

... for delivering minimal quantity lubrication to the work piece either through the tool or externally. The precise method of delivery via finely dispersed droplets of oil in a vapour means just the right amount of lubrication ...

... Automated Precision Lubrication - OnTrak's automated lubrication adjusts based on the actual condition of the bearings, ensuring optimal lubrication, extending the life of the bearings, ...

... technopolymer The modular structure, made using snap assembly of the single elements, allows you to adjust and direct the lubricating jet with maximum flexibility, while maintaining stability in operation even in the ...

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining