- Machine-tools >

- Machining Center >

- Machining for the aerospace industry

Machining for the aerospace industry

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

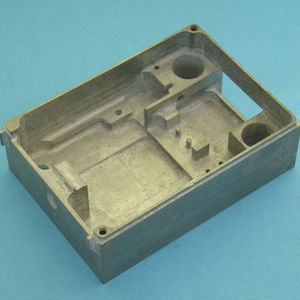

... made by AISI316Ti,This product uses AISI316Ti as the main raw material and undergoes CNC Milling process without surface treatment. It is mainly used in the aerospace field. It has the ...

This product uses 2024 aluminum as its main raw material and undergoes CNC Milling process without surface treatment. It is mainly used in the aerospace field. It has the advantages of ...

... machinery manufacturing company. Over the past few years, we have produced many high-quality stainless steel CNC parts for them, building a strong relationship of trust. This time, they need a new batch of custom stainless ...

... compared to other engineering ceramics. Because it has been a popular ceramic material, we have extensive experience in machining it. Machining to micron accuracy is possible.

Top Seiko Co., Ltd

... spreaders ■Semiconductor heaters ■Substrate material for high power, electronic devices ■Heat transfer components used at high temperatures ■Components exposed to semiconductor process chemicals and ...

Top Seiko Co., Ltd

... Low thermal conductivity Zirconia is an excellent thermal insulator due to its very low thermal conductivity. ■Good Chemical Property Zirconia resists acid and alkali attacks. ■Excellent wear resistance ...

Top Seiko Co., Ltd

... surface milling/grinding milling of edges/ends Using our double-head milling machine, we can machine your steel plates with great precision and in record time thanks to our automated machining ...

thyssenkrupp Materials

The newly acquired plastic machining capability allows us to improve the moulding precision and perform retouch operations on site. Production of tools Plastic machining, a technology we introduced ...

... ) and inspection reports (CMM, FAIR, measurement report) upon request. Advantages of CNC Milling with Xometry Rapid Turnaround Using the latest CNC milling machines, Xometry produces highly accurate ...

Xometry Europe

Milling, Turning, Assembly, Unit Parts, Small and Large Series, CFAO: (files - DXF, DWG, IGES, PDF ...)

... range of services: High precision mechanics Undercutting – Mending Turn mill center – 8, 6, 4, 3 and 2 axis Milling – 5, 4 and 3 axis 3D Monitoring Engraving Production and mounting of subassemblies All ...

... 150.000 hours of machining annually guarantees flexibility and the ability to satisfy our Customers’ requirements. The machining process includes the use of honing machines, boring machines, ...

Our CNC machining operation is set up with over 60 CNC machines to cover the full spectrum of machining services including turning, milling, drilling and grinding. Our part envelope is up to a 1.5M cube ...

stainless steel machiningClever-Cut®

The Clever-Cut® Service 3D abrasive cutting, high pressure water jet cutting, 3D milling and 3D machining Our large machine enables dimensionally accurate 3D cutting in commission by water jet.The dimensions ...

Clevercut

... about your needs for custom milling and custom micro machining. Together we can find the perfect solution for your project. MICRO MILLING ADVANTAGES Multi axis machining ...

Mekoprint A/S

... five-sided modular multi-station CNC machining centres also feature extremely short chip-to-chip time, with separate loading and unloading stations. Simultaneous machining with five machining ...

Dawson Shanahan

Production and processing of parts on CNC milling machines of dimensions X-1500, Y-600, Z-600. Production or finishing of parts on tool universal and vertical NC milling machines dimensions of the work ...

... , for all sectors of the industry. Specialists in parts for food processing machinery, packaging, and machined plastic parts for the cosmetics and perfumery sector. We have a wide range of machinery that covers most ...

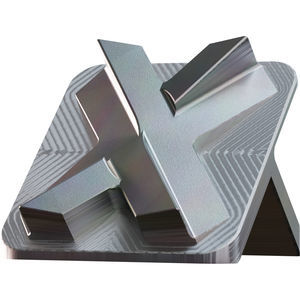

High-Efficiency Machining for Complicated Workpiece Shapes Using the Latest 5-Axis Machine

Dainichi Manufacturing Co., Ltd.

Manufacturing Range: 750x510x420 mm; Quantity: 248 sets

Dongguan Turnxon Precision Co., Ltd.

... such as the marine, food and chemical industries CONS It may be prone to stress corrosion cracking in some environments Not suitable for applications at very high temperatures MAIN ...

Weerg

Specialized in single piece, in different materials. We manufacture all kinds of parts and prototypes through CNC milling, mainly specialized in single piece, in different materials such as tempered steels, stainless steels, aluminums, ...

Mecanizados Goerna S.L.

... customers in all industries. The most common areas are aerospace, automotive, electronics, machinery, manufacturing, medical devices, oil & gas, and robotics. CNC Milling Our factory ...

... using CNC (Computer Numerical Control) machining techniques. PEEK's exceptional mechanical properties, chemical resistance, and thermal stability make it a preferred material for various industries. During ...

... ESM ESM was created by a group of passionate engineers and technicians that have worked in multinational factories across industries. The group decided to combine their talents, recruit likeminded individuals, and build ...

... in PA66 GF50 - blades in AISI 304L, thickness 0.8mm, black polished finishing Specific product application: automotive industry

Company MASAM, holder of AS9100D certificate produces components primarily for the aerospace industry. The maximum weight of an individual piece is limited by the load capacity of the handling equipment ...

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining