- Production Machines >

- Plastics Processing >

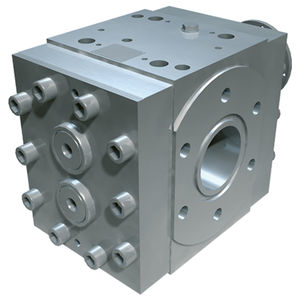

- Melt pump

Melt pumps

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

Equipping a gear pump in front of the extruder, checking pressure before the pump and contolling the speed of extrusion, which can minimizing pulsation and iregular material feeding and ensures the polymer ...

... cup ensures extended packing seal life Reliability - Eliminating downtime, the unbalanced air valve ensures stall-free pump operation Durability - Optional Ultra-Coated (ceramic) Plunger Rod and Tube for superior ...

ARO, Ingersoll Rand

Piston Pump 2 ball 15:1 Ratio 10'' Air Motor Max. flow per minute: 68.6 l/min (18.1 gal/min) Fluid pressure range: from 31 to 90 bar (1350 psi) Inlet: 2" NPT Outlet: 1-1/4"

ARO, Ingersoll Rand

Overview & Features Integrated wet cup ensures extended pump life Reliability - Eliminating downtime, the unbalanced air valve ensures stall-free pump operation Durability - Hard chrome ...

ARO, Ingersoll Rand

... The GENIPUM melt discharge pumps are specifically created for this task GMB booster gear pumps are used in the polymerization process to increase the pressure of medium to high viscous ...

Flow: 4 l/min - 12 l/min

Warm melt extrusion systems, with reliable performance for all applications that require a constant monitoring of product heating to preserve its chemical characteristics. The Touch Screen panel has a simple and intuitive ...

LARIUS SRL

Flow: 12 l/min

Warm melt extrusion systems, with reliable performance for all applications that require a constant monitoring of product heating to preserve its chemical characteristics. The Touch Screen panel has a simple and intuitive ...

LARIUS SRL

Flow: 12 l/min

Warm melt extrusion systems, with reliable performance for all applications that require a constant monitoring of product heating to preserve its chemical characteristics. The Touch Screen panel has a simple and intuitive ...

LARIUS SRL

TWIN PUMPS Tapflo PE & PTFE series pumps may be fitted with double in/outlet to achieve ”two pumps in one” for blending, mixing or recirculation of liquids. The liquid ...

Flow: 0 l/min - 5 l/min

... Delivering accurate, repeatable and low-pulse flow rates in a compact size, the 100 series has a spring-loaded track to provide pressure control that can be set for standard and higher pressures. Pumps ...

Melt pumps for extrusion The extrusion gear pump is mainly used in connection with extruders or kneaders. They lower the naturally existing pulsation and uneven transportation, particularly ...

... range of melt pumps. The BKG® MHDP high pressure melt pump is designed for high pressure polymer extrusion applications. The BKG® MHDP is a high-pressure melt ...

Nordson Polymer Processing Systems

... strainers, high requirements are placed on pumping consistency and extrusion lines. The new gear pump series extrex⁶ RV/RB from MAAG raises the performance of gear pumps for elastomer extrusion to new ...

Maag Germany GmbH

... replacement gears that the operator needs to have on hand for replacement. SIMPLIFIED USE, OUTSTANDING RESULTS Operating it is incredibly easy. A gear pump is, in fact, much more complex to operate, ...

The main function of the gear pump as a component of the extrusion equipment is to keep the flow and pressure of the plastic melt flow to the die at a continuous and constant level. The quality of the ...

... eliminated thanks to the gear pump's attenuating effect. Other advantages of gear pumps include the facts that waste products that occur internally can be reprocessed without problems and that the pump ...

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining