- Industrial machines and equipment >

- Furnace and Heat Treatments >

- Melting oven

Melting ovens

Maximum temperature: 300 °C

... partsVideoApplication:SDIDB413 Intelligent Drying Oven can be used to determine moisture content in coal, coke and solid biomass fuel and is applicable to drying, baking, wax melting and heat treatment ...

Maximum temperature: 1,300, 1,100, 1,200 °C

... of melt and crucible due to heating from 4 sides, superb metal quality, good crucible lifeHeat-resistant cast-iron ring on removable refractory concrete cover protects crucible against ...

ThermConcept Dr. Fischer

Maximum temperature: 250 °F

... Hardening Heat Treat Furnace & the Keith Bench Top Annealing Heat Treat Furnace – the Keith Standard 2250F Rated Bench Top Assaying Furnace comes in a variety of model sizes and configurations. ...

Maximum temperature: 1,500 °C - 1,700 °C

The rotary furnace is versatile equipment capable of processing a wide range of materials. It is characterised by its customisation in terms of design. The refractory products developed by Insertec respond to these ...

INSERTEC INDUSTRIAL FURNACES INSERTEC, S.L.U.

The application of an infrared oven in the surface finishing industry is melting the powder before the pieces are going into a high temperature oven.

Highly robust and reliable Circular furnace offering ideal features for mass melting of aluminium scrap and alloys. Extremely robust equipment with superb melting speeds. The furnace ...

Maximum temperature: 1,150, 1,100 °C

... with various capacities: Mini-heat: stationary electric crucible furnace for melting aluminum, zinc, brass, copper, bronze, silver and gold scrap Mini-HORCB: gas or diesel oil tilting ...

HORMESA CONTICAST HORNOS Y METALES S.A.

Static melting furnace LAMPO, Made with Fossati certified High Refractory material and protected by AISI Metallic Carpentry.

F.LLI FOSSATI S.R.L.

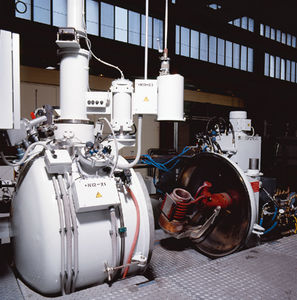

OTTO JUNKER MF induction furnaces are proven and versatile solutions refined over many years. Designed for melting, holding and pouring any type of metal, these high-performance systems embody state-of-the-art ...

OTTO JUNKER GMBH

For artistic, bronze, brass, copper foundries. Crucible capacity from 400 Kgs of copper.

F.I.M.O. SNC DI REINA M. & LONGHETTI S.G.

The melting furnaces MF are used for the energy-efficient melting of clean input material such as block metal or clean production return scrap. The melting furnaces ...

LOI Thermprocess - Tenova Metals Division

Maximum temperature: 300 °C - 400 °C

vacuum pyrolysis cleaning furnace is to remove polymer from metal parts, such as spinnerets, meshes, extrusion screws, breaker plate...etc. What's the electric pyrolysis cleaning furnace? Vacuum Spinneret Cleaning ...

Maximum temperature: 5 °C - 300 °C

Width: 520, 640, 720 mm

Height: 480, 590, 670 mm

... Product introduction: ●Provide for the industrial factory, labs, research and other departments, for Drying, baking, melting and sterilizer use. Features: ●Three kinds of controller types Pointer controller, ...

Fusing and bonding furnaces are utilized to join high-strength and refractory metals – those that are either difficult or impossible to weld. The bonding process involves applying high temperature and pressure to similar ...

Maximum temperature: 0 °C - 700 °C

Customized industrial infrared ovens for baking, drying, melting, pre-heating and pre-gelling The heating technology used is mainly electrical infrared (short-wave and medium-wave infrared) or gas ...

Slag pot is also called casting ladle, slag bucket, or slag ladle. It is important container holding high temperature liquid steel slag in the process of steel making. With richly experience and advanced casting equipment, CHAENG has ...

The Furnace 6 by Aseg Galloni Spa is a melting furnace which is just easy to use because of its use-friendly controls. For this specific unit, it comes with a high melting ...

ASEG GALLONI SPA

... You will find that we are determined to provide you with the parts you need, when you need them. Batch Ovens Include: SANITATION The entire oven is constructed of stainless steel and rated for full washdown.

Maximum temperature: 1,280 °C

Capacity: 75 l

Width: 760 mm

... Cone 6a or Orton Cone 6. The kiln volume of this toploader TE series can be increased by up to 50% by simply fitting or even retrofitting an additional heatable extension ring (ZWR). Mount the ring, connect the kiln ...

Maximum temperature: 1,600 °C

20t smelting electric furnace rated capacity:13000kVA,3000KVar rated power:2×6000kW,8000~12000KW Induction Melting Furnace,Medium Frequency Power Supply,Power Transformer 1.GENERAL The melting ...

Shanghai Electric Heavy Machinery Co., Ltd.

The Most Effective Melting Furnace Technology in The Market Maximize Metal Recoveries Cost Effective Low Energy Consumption Sustainable Energy efficient solutions. Oxy fuel and hybrid combustion. ...

Maximum temperature: 900 °C - 1,800 °C

500KG Induction Furnace for Melting Scrap Steel, Iron, Copper, Aluminium The induction furnace body mainly includes: Open furnace body, furnace ...

Tangshan Juntong Technology Co., Ltd.

Consarc offers Induction Skull Melting (ISM) furnaces which is a method of melting metals in a segmented water-cooled copper vessel while under vacuum or controlled atmosphere using an ...

CONSARC

... stringent requirements towards cleanliness and safety, the cold crucible induction melting and casting method is the right solution. This process is also known under Induction Skull Melting ...

ALD

Maximum temperature: 100 °C - 1,200 °C

Capacity: 2 l

Product Description: 1. Mirror stainless steel mouth, long-term use will not change color. 2. Imported double insulated ceramic liner, stable performance 3. Vacuum forming polycrystalline mullite fiber furnace, high efficiency ...

Huanghua Faithful Instrument Co.,LTD.

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining