- Production Machines >

- Other Manufacturing Equipment >

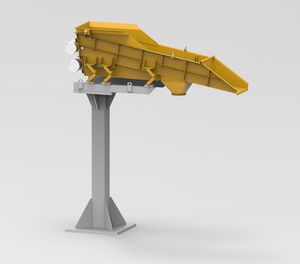

- Metallic powder screener

Metallic powder screeners

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

Weight: 300 kg

Capacity: 98, 29, 37 kg/h

Engine power: 0.26 kW

... automate metal powder sieving directly from an Additive Manufacturing (AM) machine. A highly automated, ultrasonic sieve for recycling and processing metal powders. ...

Weight: 100 kg

Capacity: 1,008 kg/h - 1,920 kg/h

Engine power: 0.17 kW

... ultrasonic sieve that uses a single 350mm diameter mesh screen to process fine metal powders into flasks/barrels. A non-automated, low volume or research friendly metal powder ...

... increase powder consumption with ease. Advanced connectivity, enabling remote optimization and monitoring. Connect to plant communication protocols like OPC-UA and data logging to optimize your powder ...

... The Hi-sifter powder screening machines are offered in both a single or double deck design. The simple design of the machine allows for quick screen mesh cloth changing and minimal down time between ...

Screening surface: 2.4 m²

Noise level: 80 dB

Introducing the Hi-E, Elcan’s latest advancement in high “G” force, high volume, linear motion separating and drying rectangular screening machine. This technology works on the principle of resonance; exciters located underneath the screen ...

Screening surface: 765 cm²

... chrome-nickel steel in various surface finishes The UFS 765 ultrasonic screening machine was specially developed for screening metal powders when feeding 3D metal ...

... manufactured parts or broken tools cannot be avoided? No problem – using a screener from Lanner will reliably separate the tramp metals and the further processing will work out fine. The screeners from ...

Weight: 6,500 kg

The Ultra ‘3Way’ has been designed to offer recyclers and materials management companies a compact three grade screen that can be loaded and operated from one side, a first in a screen of this class. The unit features a variable speed ...

Opening of the mesh: 25 µm

Engine power: 40 W

Noise level: 60 dB

This machine used for powder reclaim purpose. Lots of Titanium and Aluminium powder can be considered to be recycled for re-use after 3D printing finished. During the sieving job processing, inside environment ...

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining