- Production Machines >

- Other Manufacturing Equipment >

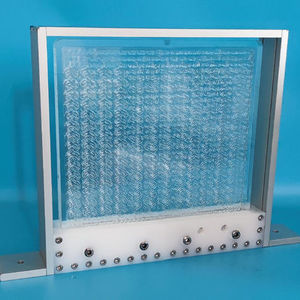

- Micro reactor

Micro reactors

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

The CM-D series continuous flow reactors is a high-throughput glass microreactor processed from high borosilicate float glass. The four-layer structure design includes the heat exchanger in the reactor ...

Laryee technology co.,ltd

... Photocatalytic reactor. The process of photochlorination, water splitting, aflatoxin production, sulfonation, sulfoxidation, and nitrosylation can be performed successfully using this reactor setup. The ...

Laryee technology co.,ltd

Electrochemical synthesis is the use of electrical energy to drive chemical change; using electricity to replace toxic and costly chemical reagents. This allows cleaner and cheaper syntheses with greater production efficiency and at reduced cost

Laryee technology co.,ltd

... flow reactor can be used with existing pumps & thermostats, or supplied as total systems on request. Our industrial flow reactors are modular glass reactors for the performance of ...

Laryee technology co.,ltd

... continuous flow microchannel reactor system for reaction screening & process optimisation. Its modular design gives the user flexibility on the number of feed lines, reactor type & volume.With glass ...

Laryee technology co.,ltd

The welded metal micro-reactor adopts the latest seamless welding technology, which realizes the welding of the entire plane instead of the welding corners, and through a special process, it is possible ...

Laryee technology co.,ltd

The Micro Batch System 2500 is Parr's smallest ever family of stirred reactors, available in a number of configurations. With reactor volumes of 5 mL or 10 mL, independent reactor ...

This Parallel Reactor System incorporates five 160 mL, 4560 Series Stirred Mini Reactors rated for use at 350 °C and 3000 psig / 200 bar. Each of the reactors has a dedicated ...

The H-Cube® Mini Plus is a safe, powerful and affordable flow reactor that generates high-pressure hydrogen with the electrolysis of water, allowing chemists to perform catalytic hydrogenations from atmospheric ...

THALESNANO Inc.

The H-Cube® Pro hydrogenation flow reactor offers higher throughput and wider temperature capability for more advanced applications. Active cooling for more selective reactions is included, as well as real-time reaction ...

THALESNANO Inc.

The H-Cube® Pro Hastelloy is designed to extend the available reaction space of its renowned stainless steel counterpart, the classic H-Cube® Pro. All wetted parts are made from Hastelloy C for improved chemical resistance. With the H-Cube® ...

THALESNANO Inc.

... of batch, flow, stop-flow and CSTR photochemical reactions. Options for multicolor and UV LEDs enable you to apply up to 7 wavelengths, in addition to white, even simultaneously. FEATURES Batch, flow, stop-flow and ...

THALESNANO Inc.

... cartridges heterogeneously Available reactors and holders The Phoenix Flow Reactor™ is a powerful and versatile heating unit capable of reaching temperatures up to 450 °C. A big selection of ready-made ...

THALESNANO Inc.

... available to organic chemists for the synthesis of novel structures, it has also been shown that chemists employ a relatively small chemical technology toolbox both in terms of the set of chemical reactions used and ...

THALESNANO Inc.

Amar has been a pioneer in the flow reactor / microreactor area in India. We have several models to offer with various specifications. We offer cost-efficient alternatives to expensive imported models ...

Amar Equipment Pvt. Ltd.

... faster transfer of process from laboratory to pilot/commercial scale manufacturing ADVANTAGES OF CONTINUOUS FLOW REACTORS OVER BATCH REACTORS: Better mixing & very high heat transfer area per unit volume Faster ...

Amar Equipment Pvt. Ltd.

... faster transfer of process from laboratory to pilot/commercial scale manufacturing ADVANTAGES OF CONTINUOUS FLOW REACTORS OVER BATCH REACTORS: Better mixing & very high heat transfer area per unit volume Faster ...

Amar Equipment Pvt. Ltd.

... testing through different configurations and options. The Microactivity Effi is a compact reactor that is completely automated. It is equipped with cutting-edge process control technology in the market. ...

Process Integral Development Eng&Tech, SL

The new Microactivity SOLO reactor is an introductory catalyst testing equipment using the latest technology in process control developed for the Microactivity Effi. It is a very compact unit saving additional ...

Process Integral Development Eng&Tech, SL

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining