Mills

Demolition pulverizer Rotar Demolition Pulverizer Incredible crushing power combined with tremendous cutting power makes the Rotar Demolition Pulverizer the perfect pulverizer ...

Rotar

Output: 40 kg/h - 3,200 kg/h

Motor power: 4, 8, 15 kW

... Comex jet mill construction allows a precise nozzle position control which is of critical importance for efficient grinding. Capacity increases have been experienced when old jet mills have been replaced ...

Final grain size: 3 µm - 300 µm

Motor power: 370 W

Dry grinding systems, which include ball mills, are usually very complex and complicated. They require ball mills working in the closed circuit with an air classifier and a complete circuit has to operate ...

Final grain size: 200 µm

Rotational speed: 50 rpm - 3,000 rpm

Machine width: 270 mm

A compact benchtop grinding mill with powerful and shear crushing capabilities IQ MILL-2070 makes the sample grinding process into a simple pre-treatment operation. By using a special high elastic belt ...

Rotational speed: 0 rpm - 50 rpm

Fully Computerized mills with Automatic mixing of the batch FULLY COMPUTERIZED MILLS WITH AUTOMATIC MIXING OF THE BATCH From manual versions to fully automatic hands-free computerized mills ...

Labtech Engineering Co., Ltd.

Output: 190, 800 t/h

Machine weight: 12 t

Range of application Continuous dry and wet grinding of coarse-grained materials to fine-ground and ultrafine-ground products. Ground product separation Dry grinding: Pneumatic extraction from the surface of the agitated media ...

Maschinenfabrik Gustav Eirich GmbH & Co. KG

Final grain size: 20 µm - 500 µm

Motor power: 30, 75, 130, 225, 400 kW

Machine length: 2,500 mm - 10,500 mm

... for fine grinding of industrial minerals and hard materials for ceramic applications Features Horizontal drum ball mill Continuous process Advantages Simultaneous grinding and drying possible ...

Maschinenfabrik Gustav Eirich GmbH & Co. KG

Final grain size: 20 µm - 400 µm

Output: 50 kg/h - 30,000 kg/h

Motor power: 11, 22, 45, 90, 160 kW

Dry grinding – continuous for desagglomeration and drying of soft materials Features Impact/Attrition mill Incorporated air classifier Advantages Simultaneous grinding and drying possible Feed material ...

Maschinenfabrik Gustav Eirich GmbH & Co. KG

... offer our clients Ball Mill. Our products are made using fine quality raw material and state-of-the-art technology. At all levels of production the quality is maintained and vouched for by our team of professionals. ...

SUPERTECH INTERNATIONAL PVT LTD

... where from this mixture is stored into Master Hopper. Next, the mixture thus collected into master hopper, is carried to BALL MILL for the final grinding. After final grinding the finished product is passed into the ...

SUPERTECH INTERNATIONAL PVT LTD

... refractory material, ore dressing of ferrous metalglass ceramics, non-ferrous metal, etc. Also known as pebble mill or tumbling mill, the ball mill is typically designed to form a ...

SUPERTECH INTERNATIONAL PVT LTD

Dibir Group builds triple roll mills, indispensable tools for grinding different types of paste and high concentration products, especially those which are temperature sensitive. Like most Dibir products, triple roll ...

Motor power: 2,200, 5,500, 7,500, 9 W

Machine length: 1,245, 760, 990 mm

Machine width: 360, 600, 810 mm

Crusher is feature by a series of knives assembled on two parallel shafts with opposite rotating direction. It stops automatically at the time of the presence of parts. In the model with extraction, the parts left automatically. Crushing ...

Motor power: 18 kW

Crusher is feature by a series of knives assembled on two parallel shafts with opposite rotating direction. It stops automatically at the time of the presence of parts. Crushing is desirable to reduce volume in order to optimize ...

Alpine Microburst AMB The new spiral jet mill Alpine Microburst (AMB) is a practical addition to our proven AS spiral jet mills and AFG fluidised bed opposed jet mills. This is because ...

HOSOKAWA ALPINE

Motor power: 1, 2 kW

Machine weight: 120, 100, 200, 300, 500 kg

... energy-saving The unit is used for crushing and milling of bulk materials with a tendency to form agglomerates, clods and lumps. Bulk materials containing agglomerates, clods or lumps, are fed into the AZO lump breaker ...

Output: 3 t/h - 40 t/h

Motor power: 77.2 kW

Machine length: 1,200 mm - 3,000 mm

... other milling system and method. In addition, it requires comparably low capital expenditure and has an excellent cost-benefit ratio. Four decades of practical experience have established the efficiency of GEA‘s steeping ...

The medium flows steadily through the RotaCut. Foreign matter (stones, metal parts, etc.) is separated out based on its size or weight and can be easily disposed of later via a cleaning port. All floating and suspended substances within ...

Vogelsang

The LiSEC float glass breakout system automatically breaks the trim cut at the front, the remnants at the trailing edge, as well as the X and Y sub-plates continuously, quickly and with consistently high breaking edge quality. Thanks ...

The scrap is gravity-fed directly from the processing machine, requiring no conveying or manual handling. Multi-position swivel outlet pipes make an easier connection to the flexible hose of the hopper loader. The regrind collection bins ...

Output: 15 kg/h - 600 kg/h

Motor power: 4 kW - 37 kW

Machine width: 200 mm - 410 mm

• Optimized cutting angle for smooth acception of skeletons to the rotor • Low speed rotor • Ergonomic, modern design • Continous infeed speed • Low maintenance • Noise level < 85 dB(A) • Optimum granulate quality The coarse-grained ...

... Versatile applications AG milling extends itself to many applications due to the range of mill sizes available. AG mills can accomplish the same size reduction work as two or three ...

Metso Corporation

Motor power: 90 kW - 450 kW

Machine weight: 6 t - 31 t

Gentle and fast disintegration of composite materials With the ADuro QZ, ANDRITZ has revolutionized traditional shredding technology. The machine does not use any cutting tools, but breaks up the input material gently and quickly by ...

ANDRITZ Recycling

Rotational speed: 420 rpm

Output: 400, 600, 750 kg/h

Motor power: 22 kW

The SPEEDGRINDER is a so-called "skeleton grinder" which grinds the residual skeleton which is produced in the thermoforming process after the packaging has been cut out. The crushed smallest parts can then be fed back into the extrusion ...

Output: 23, 30 t/h

... control and separation. The FAM product range includes impact mills, roller mills, hammer mills, ball mills and rod mills, as well as appropriate roller screens.

FAM

Output: 500 kg/h - 1,250 kg/h

... there a wide range of crushers and mills. For this reason, the planning of grinding systems almost always requires special solution approaches to the product and the firm. Collection: • Fine ...

Output: 0 kg/h - 40,000 kg/h

• Capacities up to 40,000 kg/h* (Inline) • Capacities up to 10,000 kg/h** (Stand- alone) • From lab to industrial scale Functions: • pre-grinding • pulping • mashing Main applications: • fruit and vegetable • soya beans ...

ProXES GmbH

Output: 0 g/min - 1 g/min

... on our Jet Milling technology, the MCOne works independently with just a nitrogen bottle, with the process at a constant temperature (endothermic). The powder is fed at subsonic speeds (approximately 50 m/s) into the ...

Dec Group

Motor power: 6, 30 kW

The SML 16 models are a series of particularly wide machines with smaller rotor diameters for the processing of thin-walled panels and skeleton waste, directly in the deep drawing line. The very low design of the granulator makes it suitable ...

HERBOLD Meckesheim

Motor power: 1 kW

Machine width: 550 mm

Machine height: 1,420 mm

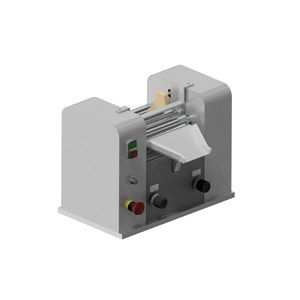

The Grain is a machine used to crush previously roasted nuts (hazelnuts, almonds, pistachios...) in order to reduce them to grains. The product is fed into the loading hopper and it passes through the rollers below, which differ in ...

Selmi

Rotational speed: 3,600 rpm

... are processed at lower flow rates to stay within the pressure limit. Up to 50% more flow rate with less heat than other mills Easy to adjust; calibrated ring sets spacing; no special tools; less downtime; may be adjusted ...

Your suggestions for improvement:

the best suppliers

Subscribe to our newsletter

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining