- Production Machines >

- Other Manufacturing Equipment >

- Mill production line

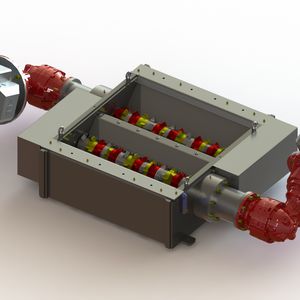

Mill production lines

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

Plants for grains and dried fruits powder used to optimize and automate the production process and processing products such as hazelnuts, almonds, pistachios, peanuts, etc. Each plant is designed for ...

Rotational speed: 30 rpm

Output: 30 t/h

... remote management to achieve more accurate management and production operations, which can reduce equipment failure. (3) Flexible operation Production management personnel can view production ...

Rotational speed: 12 rpm - 15 rpm

Continuous grinding ensures greater productivity, plant engineering solutions in small spaces, computerized control and management of production parameters. We are able to propose a broad range of continuous ...

ICF & WELKO

Output: 20 t/h - 300 t/h

... / steel slag / nickel slag / manganese slag powder production line with an annual output of 200,000-1,500,000 tons. So far, CHAENG has established successfully more than 100 slag production ...

CHIPFLEX is based on a mobile electric chipper located on a railway, and equipped with a handling system as a grapple crane. The operator chooses the wood in one of the bins assigned in advance along the way and feeds the chipper. Chips ...

Output: 50 kg/h - 900 kg/h

The advantages of breaking-up ferrous or non-ferrous chips A higher market value for your shredded chips for their reclamation in recycling channel thanks to chips densification. Volume reduction, therefore limited CO2 emissions (fewer ...

... belts which due to their special arrangement are providing the fanning effect. The KUPER FFM is always used as part of a production line with the KUPER KLM and other transportation systems.

Rotational speed: 10, 12 rpm

Motor power: 160, 185, 200, 220, 250 kW

They are used for batch milling and mixing of ceramic glaze and pigment. Ball mills 3T and smaller than 3T are with steel support. Ball mills bigger than 3T are with concrete base.

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining