- Machine-tools >

- Machine Tool Accessory >

- Modular chuck

Modular chucks

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

... concentricity, axial run-out and repeatability Light weight and reduced height thanks to compact design High flexibility thanks to modular system Fast change of clamping sleeves thanks to central clamping screw

Rotational speed: 4,000 rad.min-1 - 8,000 rad.min-1

... • Manual lubrication • Collet chucks with exchangeable and oil-resistant vulcanized rubber • For use on lathes. • Ideal for bars and pipe machining on the main spindle. • Maximum flexibility thanks to modular ...

... machining by removing the internal workpiece stop. • Axially fixed collect chuck, no axial tension against internal workpiece stop. • Manual lubrication • Collet chucks with exchangeable and oil-resistant ...

Clamping range: 32 mm

Coating: without OAL l₁: 72 mm shank diameter d₂: 32 mm

EMUGE-FRANKEN

Clamping range: 40 mm

for Gigant-modular-sprinter Gr.12 nominal size: 40 OAL l₁: 103.4 mm

EMUGE-FRANKEN

Clamping range: 100 mm

for Gigant-modular-sprinter Gr.15 Technical details OAL l₁: 126 mm

EMUGE-FRANKEN

Clamping range: 6 mm - 34 mm

The compact collet chuck with Quick-Point® zero-point interface is designed for milling round components with clamping diameters of 6 - 34 mm and uses commercially available ER-50 collets. Its slim design offers excellent ...

BT Arbors for Modular (Screw Type) Indexable End Mills DIN ISO 7388-2 AD (JIS B 6339 MAS 403 BT)

HSK-A for Modular (Screw Type) Indexable End Mills ISO 12164-1 (DIN 69893-1) HSK FORM A

BT Arbors for Modular (Screw Type) Indexable End Mills DIN ISO 7388-2 AD (JIS B 6339 MAS 403 BT) BT Tool Holders for rotating tools, commonly used in high-speed machining, are designed to provide a secure and precise ...

Clamping range: 50, 63 mm

... long reach up to 6XD for both roughing and finishing. It can be fitted to all types of machine spindles with ISCAR CAMFIX modular system, allowing maximum flexibility. WHISPERLINE offers efficient performance in a ...

ISCAR Tools

Seco-Capto™ is a leading quick-change modular tooling system for quick setup and replacement of cutting edge holders. Its robust product design allows retaining excellent stability and high positioning accuracy. The product ...

The BIG KAISER modular tooling system offers standard solutions for OD turning on machining centers. The intermediate and large diameter systems allow the use of two TW series heads for balanced roughing and all finish ...

BIG KAISER

Clamping range: 12.4 mm - 22.4 mm

... High Accuracy & Rigidity Pull-back design draws workpiece securely against a part locator for 'dual-contact' rigidity. Modular Design All Mandrel models have a common flange configuration, enabling full interchangeability ...

Clamping range: 3, 2, 4 mm

Ultra Hard Cutting Materials Cubic Boron Nitride (CBN) and all Diamond Cutting Materials: Monocrystalline Diamond (MCD), Polycrystalline Diamond (PCD), CVD-D Diamond.

It is a line of high precision modular tool-holders used to perform with extreme flexibility and rigidity operations of boring, milling, drilling and tapping. The MHD coupling is the strength of the Modulhard’andrea: ...

D'Andrea S.p.A.

... assembled on the turret, while changing the adapters only with the model spcifially needed for every machining. The MTSK modular system is derived with M.T.'s know how from the popular HSK-T system, which foresees ...

The modular tooling system offers better efficiency, material selection and heat treatment. For example, the serious damage on tool holders caused by broken inserts can now be easily and economically replaced.

The Diebold Modular System (DMS) consists of a basic tool holder and shrink chuck reductions and extensions of various lengths and bore diameters are mounted. When using DMS, the number of tool holders ...

Helmut Diebold

... specific flange mounted holders for use with SA part-off modules, blades, monoblock holders, and monoblock holders SE. The modular holders can be mounted either normal or upside down. They are suitable for part-off range ...

Arno Werkzeuge

Rotational speed: 5,400, 6,000, 5,500, 5,000 rpm

Flexibility thanks to the modular system I.D., O.D. or jaw clamping – it's easy with the B-Top3 modular system. Everything fits together. With the MANDO Adapt segmented mandrel, you can change ...

HAINBUCH GMBH SPANNENDE TECHNIK

... - better sealing - modular shank system MS, W - horizontally, vertically applicable - applicable for left and right handed threads ADVANTAGES - optimal force distribution - less maintenance required - to avoid ...

Bilz

Topics such as energy efficiency and conservation of resources are becoming increasingly important. In the machining sector these issues are affecting above all the machine tool and the cooling lubricant. There is particularly high potential ...

The modular tool-holder system from SAU offers a flexible line of modular units. Their products are a suitable solution for almost all tough machining conditions. The system conforms to DIN 69893-A ...

Clamping range: 1.1 mm - 5.1 mm

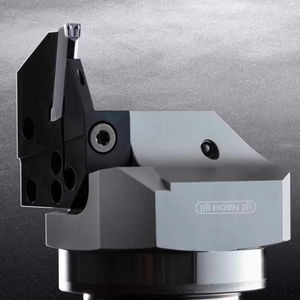

Modular holder system With these holders, HORN offers a modular system with which the user can adapt tool holders and inserts directly to match the machining task and machine interface.

Rotational speed: 5,000, 6,000, 7,000 rpm

... the filled-out form. The pull-down chucks are available in the following design: • Through hole chuck for bar machining • Endstop chuck with removable endstop for insert parts and ...

... connection for secure clamping Modular system that allows you to use a variety of different shanks Features Through-coolant capable Available in microadjustment for 0.00005" or 0.001 mm increments Adapts to modular ...

Allied Machine & Engineering

The modular tooling system for WEDM The EROWA Wire EDM tooling system frees up your valuable WEDM machines from unproductive setting-up and preparation times. The well-thought-out combination of vises, clamping ...

Rotational speed: 6,000 rpm

... ground for accuracy and long term performance. • Internal components are sealed to prevent chip accumulation inside chuck body • Modular chuck design can be adapted to any machine spindle ...

Microcentric

Clamping range: 68 mm

Rotational speed: 8,000 rpm

... change faster than your competitors. In addition, your driven tool adapts to your requirements in the future. Due to the modular interface, for each machining process, the ideal tool clamping can be selected. • Tool ...

EWS Weigele GmbH & Co. KG

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining