- Industrial machines and equipment >

- Mixing and Dosing >

- Multi-component batch blender

Multi-component batch blenders

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

Solutions for multi-stage manufacturing processes Metered application of fluids is increasingly becoming part of automated manufacturing processes. As a result, no dosing unit concept would be complete without the ...

DOPAG - Metering, Mixing and Dispensing Technology

Highly specialized processes cannot always be mapped with existing production concepts. Individual solutions are often required. We are a competent, qualified partner for the construction of customised metering and mixing systems. DOPAG ...

DOPAG - Metering, Mixing and Dispensing Technology

... compact, solvent free, gear pump driven metering and mixing systems. They are used to apply low to medium viscosity multiple component materials such as epoxies, polyurethanes and silicones. The material ...

DOPAG - Metering, Mixing and Dispensing Technology

gravimetric mixer-dispenserGRAVICOLOR

Flow rate: 0 kg/h - 2,200 kg/h

GRAVICOLOR doses and mixes up to six materials precisely and with maximum recipe accuracy. These modular gravimetric units are designed for injection, blow moulding and extrusion and provide throughputs up to 2200 kg/h. Independent ...

SPECTROPLUS is a gravimetric & volumetric synchronous dosing & mixing unit for diverse materials – from granules, regrind or powders to liquids and flakes. Due to the modular design of the SPECTROPLUS with only one frame size and up ...

Accuracy: 0.01 %

Flow rate: 50 kg/h

OPTI-MIX 50 Batch Blenders can accommodate up to four material components while providing throughput rates up to 50 kg/hr (110lb/hr). OPTI-MIX 50 utilizes TSM slide valve design and patented ...

TSM Control Systems

Accuracy: 0.01 %

Flow rate: 350 kg/h

The OPTIMIX-300 Series Batch Blender can accommodate up to four material components while providing throughput rates up to 350 kg/hr. The range of blenders utilises the ...

TSM Control Systems

Accuracy: 0.01 %

Flow rate: 650 kg/h

The OPTIMIX-600 Series Batch Blender can accommodate up to four material components while providing throughput rates up to 650 kg/hr. The range of blenders utilises the ...

TSM Control Systems

... the established ViscoDUO, it’s taken just under a year to carry out development work on the vipro-DUO. With this, the 2-component sector now also has a dosing head in a modular design that combines the best of both worlds ...

The static-dynamic mixer vipro-DUOMIX is perfectly suited for two-component materials with very different viscosities, extreme mixing ratios and high-pressure sensitivity. The 2-component ...

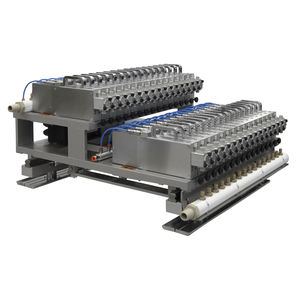

liquids mixing and metering unitMultiFlex mta®

... The MultiFlex is a very compact solution to answer the multidispensing needs. It consists of a series of mta Mini-NVD mono-component dispensers which can be controlled independently. Furthermore, each Mini-NVD dispenser ...

Accuracy: 1 %

Flow rate: 1 kg/min

Power: 5 kW

... Mixing type Dynamic mixing with adjustable mixer speed Number of metered components 3 components Output From 500 ml/min to 2.000 ml/min, depends on ratio Metering accuracy ± 1% Viscosity ...

OSV

Accuracy: 1 %

Flow rate: 10 kg/min

Power: 15 kW

... elastomers Mixing device Low pressure dynamic mixing head Number of metered components 3 basic components Number of metered addtitives up to 15 components Basic components ...

OSV

Accuracy: 2 %

Flow rate: 12 kg/min

Power: 11 kW

OSV Combi Ultra is designed for the production of a wide range of artificial stone products (solid surface, engineering stone, etc.) using the technology of dosing and mixing of multicomponent polymer compounds with mineral fillers — ...

OSV

... ratio • Height adjustable 3-component mixing block • Electro mechanical metering valves at mixing block with non return valves • Usage of disposable plastic mixing sections • Recirculation mixing block - containers • ...

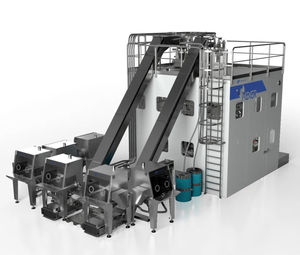

... production range of up to 1500 kg/h, and can feed up to 5 materials. Separate load cells for each component allow for constant monitoring of each component flow. If there are any changes in properties, ...

... this type, the unit weighs and blends up to four components at rates up to 450 lbs/hr (204 kg/hr). The 100 Series Blender features an exceedingly precise Micro-Pulse™ metering device. At the heart of ...

... Twin’s easy to operate and highly efficient vacuum potting machines guarantee bubble free potting for your products or components. The vacuum potting systems come with an integrated vacuum chamber and a variety of automation ...

... raw material systems that need to be heated to 50-130 °C -individual temperature control of polyol and isocyanate. -each component tank and metering system are installed in the incubator. -material tank with level ...

resin mixing and metering unitCV2 SMART

METERING AND MIXING SYSTEMS All the Demak metering and mixing systems are very precise, in fact the correct ratio among multi-components is the key-point to obtain the perfect final characteristics ...

Demak S.r.l.

... regular basis. All components are being dosed one after the other in the weighing bin, which contains a very accurate weighing system. When the weighing is done, the complete batch will fall into the ...

Ferlin Plastics Automation

The MIXER model material dosing and mixing equipment that D.B.M. Tecnologie designs, builds and installs consists of complete, customisable systems that can be used in various industrial sectors. COMPLETE DOSING SYSTEMS Our ...

... used off-line with a loader system and multiple feeders. The COLORex mixer is a great alternative to traditional high-speed mixers which are timeconsuming and costly to clean and maintain. ...

Your suggestions for improvement:

the best suppliers

Subscribe to our newsletter

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining