- Production Machines >

- Other Manufacturing Equipment >

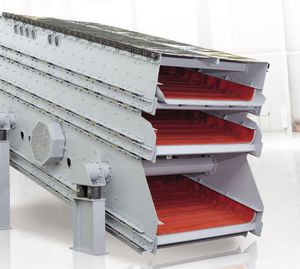

- Oscillating screener

Oscillating screeners

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

Weight: 145 kg - 2,130 kg

Opening of the mesh: min 30.0 µm

Screening surface: 0.3 m² - 8.6 m²

Highest screening quality in fine and ultra-fine screening with Tumbler Screening Machines TSM/tsi Allgaier tumbler screening machines have been setting standards in the fine and ultra-fine screening ...

Weight: 750 kg - 3,150 kg

Engine power: 0.75 kW - 4 kW

ERGA GS gyratory screen provides simultaneous screening of material into up to 5 fractions with classification efficiency up to 99%. Productive design ERGA GS screen is a sealed, dustproof housing with replaceable mesh screens inside ...

... subsequent product steps takes place on self-cleaning calibrated sheets arranged according to a precise sieving scheme. The oscillating movement is produced by a flywheel powered by an electric motor suspended on an elastic ...

... (no steel wire mesh material) Large variety of different screening outlet forms and widths Movement of left and right oscillating masses can be adjusted Vibratory characteristics can be adjusted by the number of rubber ...

Dieffenbacher

Engine power: 5, 3, 10, 7, 2 ch

... WSM's Oscillating Screen is a favorite across a variety of industries. With a screen area up to 12′ x 20′ and production capacities from 8 to 80 units per hour, WSM's Oscillating Screen provides as much ...

... The whole sieves box is fixed to the mechanical part underneath, which sustains it and generate the movement. Eight oscillating elements hold up the whole structure, causing the movement. The product that goes in ...

Weight: 1,400 kg

Screening surface: 3 m²

Capacity: 50 t/h - 80 t/h

Screen easy to move on site. Your recycling partner. • Made in France • Compact and easy to move • Recycling, calibration, multi-material recovery (wood, earth, gravel, sand, coal, compost, wood, glass, etc.) • Productivity, profitability

... transmits the torque to the oscillating device, driving the oscillating device to make an oscillating movement above the screening device, thus sorting the material in the screening device. ...

Engine power: 200 W

RTUL’s ultrasonic powder screening machine is composed of ultrasonic vibration system and sieving machine with unique technology. RTUL’s Ultrasonic Powder screening machine is used for ...

... Depending on the product and capacity, our engineers will indicate and design the best oscillating screen to meet your requirements. In oilseed processing, the oscillating screen fits into several ...

Balanced Elliptical Motion Shaker Usage: In drilling top-hole sections where heavy, high-volume solids, it can remove viscous solids and eliminate larger particles in drilling fluids. Balanced Elliptical Motion Shaker Features & Benefits: 1. ...

Large capacity Robust construction with low maintenance requirements Easy sieve removal Easy inspection cover removal Simple and precise motor alignment The Satake Milling Separator SFI is an all purpose separator for the cleaning ...

Your suggestions for improvement:

the best suppliers

Subscribe to our newsletter

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining