- Industrial machines and equipment >

- Surface Treatment >

- Painting on metal

Painting on metal

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

Our company provides painting as a surface treatment method for industrial components and products. The painting process involves applying a liquid or powder coating to the surface, which provides both ...

Surface treatments Perfect finish When you order from AWS, you can rest assured that your material has been finished to perfection and that it meets all of your requirements. Delivery in accordance with NEN-EN 1090 is also possible; ...

ANCOFERWALDRAM STEELPLATES B.V.

... treatment Our paint workshop was established in 2014, with 7 sandblasting equipment and 2 painting lines. More than 40 experienced painters provide sandblasting, painting and drying services.

... service lives – the service life of a zinc die cast mold is 750,000 – 2,000,000 shots – a factor of 8-10 higher than comparable aluminum tools Less tolerances without machine processing Higher strength, higher elongation ...

Adolf Föhl GmbH + Co KG

KERBIRIO

PAINTING It is realized in 5 spraying booth on parts after surface treatment.The main products applied are polyuréthanes, epoxy,enamel on metallic or composite elements

BONNANS

... -dip galvanising, powder coating provides maximum corrosion protection with many design options Cathodic dip painting In CDP, the metal parts are dipped in thin-film lacquer, whereby the lacquer particles ...

Collini Holding AG

... industry, it is applied on titanium or stainless steel as well as on primary light alloy parts. Substrate Performed mainly for the aeronautical industry, it is applied on titanium (treated or not) or stainless steel ...

... parts and assemblies for machines in the field of cardboard industry, various types of processing. Finishing, assembling, painting.

Painting a durable and excellent finish may extend the life of even the most resistant surfaces. Painting of iron, steel, aluminium and other metal types is a craft requiring high ...

... Numerous activities are, on one hand, internally developped, such as design, purchase, laser cutting, folding, soldering, painting, assembly, tests and shipment. On the other hand, Bieber Industrie maintains close connections ...

Bieber Industrie

WET COATING Wet coating with quality guarantee. With more than 30 years' experience, Seppeler is the right contact for high-quality wet coating. Not for no reason are we Germany's first liquid paint coater to be awarded the Qualisteelcoat ...

... Quality control. 3d inspection and report. MATERIALS WE WORK WITH INCLUDE Low and high carbon steels Tool steel Stainless steel Aluminum alloys Copper, bronze, and brass alloys Plastics Composites Specialty ...

... parts, following material, customer needs and reglementary requests (Rohs / Reach) : anodisation, zinc coating, chroming, painting, burnishing Our quality guaranty – Control report for each delivery – Care given to possible ...

A.G.C. BUSINESS CONSULTING S.A.

... available: powder coating zinc plating anodising cathodic electrophoretic coating tin-plating painting primer galvanising For electrophoretic coating, priming and powder coating, ...

Passivations are processes that make electrolytically deposited metal surfaces have a greater corrosion resistance through protective coatings on the basis of CR III through a non-electrolytic immersion chemical process. This ...

... number of employees trained in the field of painting and employees with many years of experience in the field of painting. In addition to carrying out painting work itself, the firm also ...

AÉROPROTEC specializes in the surface treatment and painting of metal and composite material parts used in the aeronautical industry, essentially to protect them against corrosion according as per specifications ...

PEINTURE AERO

Painting Industrial Metal Finishing provides corrosion resistant, wear resistant, and impact resistant paint, as well as painting for cosmetic and appearance improvement. We offer Mil ...

Industrial Metal Finishing

Process of cataphoretic painting KTL ✔ Automatic stroke immersion line ✔ Preparation of the surface: zinc phosphating ✔ Maximal dimensions of a painted component 2500 x 1100 x 500 mm ✔ Maximal weight of a single batch ...

Pomel Sp. z o.o.

Qingdao Chifine Machinery Co.,Ltd is one famous company in China which specialized in various metal casting and machining products with over 20 years experience located in Qingdao China.It covers a comprehensive range ...

Painting and anodizing When we talk about aluminium surface treatment, we are talking primarily about painting and anodizing. Anodizing seals and protects extruded aluminium. Painting ...

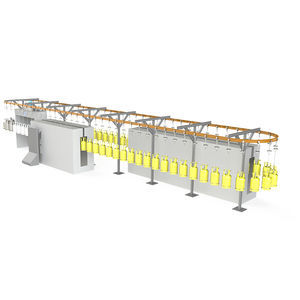

The LNG cylinder production line of EN source company is used to store liquefied natural gas. As we all know, liquefied natural gas is the most environmentally friendly and clean energy in the world, but the transportation and storage ...

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining