- Industrial machines and equipment >

- Furnace and Heat Treatments >

- Polymerization oven

Polymerization ovens

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

Maximum temperature: 300 °C

Width: 6,800 mm

Height: 3,000 mm

Belt conveyor gas furnace to perform heat treatment of bent tubes. The furnace is composed of three different sections: heating, soaking and controlled forced cooling. High speed air circulation, optimized ...

Maximum temperature: 1,100 °C - 1,800 °C

Capacity: 5 l - 45 l

Width: 150 mm - 360 mm

MSE chamber furnace is designed for use at a wide temperature ranges and different volumes in order to enable users to perform melting, thermal ageing, metal heat treatment, sintering, burning, tempering, normalizing, ...

Tunnel oven with curved conveyor with motorized rollers Our custom conveyor ovens can provide temperature controls in multiple zones according to the different stages of the heating process of your product ...

ELMETHERM

Tunnel oven with fiber glass Our custom conveyor ovens can provide temperature controls in multiple zones according to the different stages of the heating process of your product (desolvatation, temperature ...

ELMETHERM

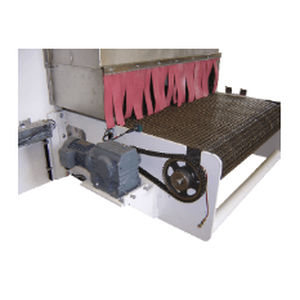

Tunnel oven with stainless steel mashes Our custom conveyor ovens can provide temperature controls in multiple zones according to the different stages of the heating process of your product (desolvatation, ...

ELMETHERM

Flatbed UV tunnel Flatbed UV tunnel for curing UV-sensitive inks and products. Efficient, reliable and easy to operate. Available with Medium Pressure lamps or LED technology. Quality: Designed for industry according to European ...

Maximum temperature: 20 °C - 220 °C

Static oven used in the necessary treatments for the manufacturing and maintenance of big electric motors, also for the nautic division. Its efficiency guarantees the best performance possible and also its durability. The ...

IDROCALOR SRL Italy

Maximum temperature: 20 °C - 200 °C

Static oven used in the drying treatments of oil and resin filled transformers. Its efficiency guarantees the best performance possible and also its durability. The internal temperature uniformity is ensured thanks ...

IDROCALOR SRL Italy

Maximum temperature: 20 °C - 200 °C

Static oven used in the drying treatments of oil and resin filled transformers. Its efficiency guarantees the best performance possible and also its durability. The internal temperature uniformity is ensured thanks ...

IDROCALOR SRL Italy

... curing oven requires as little as six feet of floorspace for cure cycles as long as four hours. Heller Vertical format ovens consume unused air space, not valuable floor space. The Heller 788 in-line, ...

Maximum temperature: 200 °C

Width: 228, 208, 178, 158 cm

Oven for drying and polymerization of screen printing inks designed for use in the textile and graphic sectors. The evaporation of water and solvents is guaranteed by a forced air ventilation. Constant ...

Maximum temperature: 170 °C

The OVEN series by Tonello includes multifunctional ovens for drying sprayed garments, and curing pigments and resins. Available in five models of different sizes and capacities. Power supply can ...

Maximum temperature: 180 °C - 220 °C

... adjacent workstands Low operating costs (long service life of components, low energy consumption) Polymerization ovens OVERSATIL Series polymerization ovens developed ...

... . Description : Drying tunnels and ovens after washing and liquid paint application Baking tunnels and ovens for powder paint application Ovens and tunnels for composite materials Single-unit ...

Maximum temperature: 200, 300 °C

Capacity: 60 l - 960 l

Air-circulation Drying Ovens KT 60/02/A – KT 1000/03/AT max 200 °C and 300 °CDrying ovens can be used for a wide range of applications, e.g. for drying, vulcanisation and polymerisation.Rugged casing ...

Maximum temperature: 200 °C

Capacity: 20, 50, 120 l

... Degassing of metal - Bleeding - Heating of metal parts for surface treatment - The vacuum avoids oxidation by air - Polymerization vacuum -> without oxidation - Degassing silicone parts for manufacturers of connectors - ...

France Etuves

Nordson ASYMTEK’s Select Cure UV-9 inline oven is ideal for top and bottom material curing in mid-to-high volume production. Using ultraviolet light as the primary cure method, the oven is optimized for ...

... switches Purge timer Fail safe, separate, manual reset, high limit thermostat Second heater contactor for electric ovens Door switch Separate power exhauster

Maximum temperature: 250, 350, 300, 400 °C

Width: 220, 300, 500 mm

Height: 230, 300, 500 mm

Depth: 130, 300, 400 mm

The UV / LED oven more particularly called UV oven is used for the polymerization of UV photosensitive adhesives. After application of the UV adhesive, the adhesive parts are placed ...

Maximum temperature: 120 °C

Description Dental articulators or several flasks in a flask press can be polymerised simultanteously. Pressure, time and curing temperature are adjustible. The heating outside the stainless steel tank is free from wear and grants ...

Your suggestions for improvement:

A curing oven polymerizes materials, primarily composites, through the application of heat. The various configurations include vertical, continuous operation (tunnel) and batch ovens.

ApplicationsThese ovens are used in the composite materials industry for polymerization, including pre- and post-treatment.

TechnologiesHigh heat is used to polymerize the treated materials. Temperatures can reach 500° C and are regulated by a ventilation system. Ovens are electric, gas or oil-fired and include safety systems in the event of the door opening.

How to chooseChoice will depend on required curing parameters, such as cycle time, temperature and air or vacuum curing. Power source, another important factor, may be affected by economic and technical considerations.

- Pre- and post-treatment options

- Expensive

- Tool contamination

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining