- Production Machines >

- Other Manufacturing Equipment >

- Powder screener

Powder screeners

Description - Applied for protective screening and separating of oversize grain - Single and double decker - Screening surface 0.50 and 0.75 m² - Continuous screening process - Optionally available in ATEX design ...

J. Engelsmann AG

Centrifugal dehydrating screens working statically they can work without special strengthening as bottoms and beds in tanks or storage and sewage reservoirs. They are used for desludging and dehydrating of small coal (preliminary dehydration ...

Progress Eco

... are typically used to sieve extremely fine and/or lightweight products (food flour, micronised materials, mineral powders, plastic powders). Should we use a typical vibrating screen, we would notice ...

Under the brand name SEFAR NYTAL we offer a comprehensive range of fabrics specially made for plansifters. The open-mesh polyester, polyamide and wire mesh fabrics are available as ready-made products, as well as roll goods. With over ...

The Vibro Separator mod. SV is principally used in mills, silo screen rooms, feed mills, seed cleaning plants, coffee sizing industries, chocolate factory, pulse classification plants. Moreover it is used for the stoning and grain classification ...

The HiColo Automatic powder cycling and recovery system has a sieving system and a unit used for meshing ( obtaining) powder. The HiColo Automatic powder cycling and recovery system ...

... high-precision materials and large processing requirements. Its screening accuracy and efficiency meets all fine and ultra-fine powder and particulate materials, and durability is widely recognized by the industry. Characteristics 1. ...

... assistance. Common Applications Include: Screening bulk materials, such as powders, plastic pellets, aggregate, or scrap metals Benefits of the EMS Electromechanical Screener Include: Force output is ...

Cleveland Vibrator

The biaxial round vibrating screen, with the patent number of ZL 2009 2 0224028.8, is utilized within the business of metallurgy, mine and coal. It is principally made out of screen box, screen, and vibration exciter and damping spring. ...

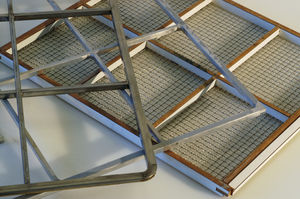

Vibrating sieves are used to remove grit and fine particles from the pellet flow. They are available in a single-deck and a double-deck version. The sieve frame is suspended in a frame made up of hollow sections by means of laminated ...

... constructed to efficiently remove lumps, foreign bodies and husks from powders and milled products. They can also be used to remove dust & fines from granular materials. Beccaria rotary powder ...

powder recycling screenerWLQ 18-85, WLQ 30-85

... machines can be specially designed to meet special requirements. APPLICATIONS WLQ sifter is special designed for light powders, and widely applied in food, chemical, pharmaceutical industries, etc.

Opening of the mesh: 100 µm - 200 µm

Powder Ultrasonic Sieving System The easy-clean sieve system can be used in any powder coating system. The Ultrasonic sieve is typically located in the powder kitchen as standard equipment ...

CST series industrial vibrating screener for classification and separation. Suitable for separating, classifying and sorting all kinds of materials into different sizes and fractions.

Opening of the mesh: 25 µm

Engine power: 4.3 kW

Noise level: 75 dB

TVS-400 series is a combination of powder conveyor andsieving station, used for explosive metal powder reclaim purpose in safe working area. Lots of Titanium and Aluminium powder can ...

Ultrasonic Screening: In enamel production lines, recycling systems used both to increase the profitability rate of companies along with the continuity of product quality. In addition to the recycling system, ultrasonic screening is also ...

STR TEKNIK MAKINA

Engine power: 1.5 kW

... normal use All the foundation support and vibrating body is galvanized and sprayed paint, and the place which contact with the powder milk is made of polished 304 stainless steel

Weight: 23 kg

Engine power: 24 W

New quality of powder sieve The sieve breaks up all the lumps and gets the used powder ready to refresh EASY TO USE Simply place used powder into the machine and press the button. The ...

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining