- Production Machines >

- Forming Machine >

- Press for the aeronautical industry

Presses for the aeronautical industry

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

Force: 5,884 kN

Opening: 750 mm

Stroke: 500 mm

600 Tm capacity with 6 double effect cylinders. Lower plate dimensions: 4.000 x 1.000 mm and removable from left to right side. Upper plate dimensions: 2.000 x 1.000 mm. Hydraulic group with pistons pump of variable flow. Speed at ...

Force: 400 tf

Rate (strokes/min): 30 p/min - 40 p/min

Stroke: 250 mm

This Large 400 Ton Mechanical Press is suitable to carry out big tasks involving deep-drawing, cutting, punching and stamping. Our Profi Press eccentric presses can be used for various applications in ...

Force: 75, 50 kN

Stroke: 500 mm

... integrated energy management and intermediate storage of braking energy for use in the high power range, e.g. in the following industries: Electro mobility Crimping cable lugs Moulding of battery packs Aeronautics Moulding ...

Force: 150 tf

Opening: 630 mm

Stroke: 500 mm

C-frame hydraulic straightening press designed to carry out sheet metal straightening work. The PCR machine workshop press is made with a c-frame structure and has an open recess, which facilitates ...

SICMI SRL

Force: 200 tf

Opening: 640 mm

Stroke: 500 mm

C-frame hydraulic straightening press designed to carry out sheet metal straightening work. The PCR machine workshop press is made with a c-frame structure and has an open recess, which facilitates ...

SICMI SRL

Force: 40 tf - 300 tf

Stroke: 500 mm

Table width: 900, 700, 1,200, 1,000 mm

Hydraulic press designed to carry out sheet metal straightening work. The PCR machine workshop press is made with a c-frame structure and has an open recess, which facilitates the positioning of the ...

SICMI SRL

Force: 5 tf - 35 tf

Opening: 0 mm - 520 mm

Table width: 500 mm - 500 mm

E-FORM X1 is an agile solution with a compact design for forming small series, excellent for prototyping. Its dimensions allow for easy placement within the production area. The silence, derived from the exclusive use of the electric ...

Meccatronica Automazioni S.r.l.

Force: 196.1, 20, 40, 50, 80 kN

Opening: 0 mm - 550 mm

Stroke: 0 mm - 500 mm

E-FORM XL1, with a solid design and a large working area, allows for better ergonomics thanks to the generous dimensions of the plates that facilitate loading/unloading and cleaning of the moulds. Each plate houses n. 5 resistances for ...

Meccatronica Automazioni S.r.l.

Force: 2,000 kN

Opening: 800 mm

Table width: 1,500 mm - 1,500 mm

... mm) the E-FORM XL1-250 pushes electric technology to reach up to 250 tonnes of force. All the advantages of an electric press with high tonnages for mass production or large parts.

Meccatronica Automazioni S.r.l.

Force: 100 tf

Opening: 1,200 mm

Rate (strokes/min): 150 p/min

Discover the Advantages of Our Advanced Mechanical Progressive Presses: Cam-Driven Ram: Unique cam design for dwell time at top and bottom dead centers Optimal conditions for tool technologies Parallel Operations: Ideal for ...

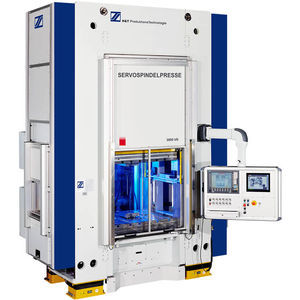

Force: 1,250 kN

Rate (strokes/min): 120 p/min

Stroke: 250 mm

The Servo Spindle Press, used as a progressive press, offers all the advantages of spindle drive technology with top-mounted motors. Specifically designed for complex processes, such as in transfer or ...

Force: 3,300 kN

Opening: 1,200 mm

Rate (strokes/min): 100 p/min

Tryout and pilot production press with four servo-hydraulic die cushion systems for fine blanking, embossing and calibrations. Tryout and pilot production press: Blanking and forming parts for drive ...

Force: 996 kN

Opening: 500 mm

Rate (strokes/min): 4,000 p/h

... weight. Moreover, Neotecman’s design is based in a double structure for press and furnace, that includes the assembly of a robot to offer a multiple billet positioning in the press, symmetric billets, ...

Force: 1,793 kN

Opening: 500 mm

Rate (strokes/min): 4,000 p/h

HV255.45i FORGING PRESS + INDUCTION FURNACE AND BAR CUTTING DEVICE Neotecman's advanced induction furnace technology integrates exclusive processes: automated loading, precise heating, and hot cutting of brass or ...

Force: 3,487 kN

Opening: 100 mm - 500 mm

Rate (strokes/min): 4,000 p/h

... weight. Moreover, Neotecman’s design is based in a double structure for press and furnace, that includes the assembly of a robot to offer a multiple billet positioning in the press, symmetric billets, ...

Force: 2.5 tf - 2.5 tf

Max. pressure: 345 bar

... pressure, the Triform model 24-5FC fluid cell sheet hydroforming press is one of the most versatile models available on the market today. Ideal for low-volume, high-mix production, this press can form ...

Force: 280 tf - 280 tf

The Triform 16-10-7 deep draw sheet hydroforming press offers a 16 inch forming space and an incredibly capable 10,000 PSI of pressure. This machine includes a 7″ punch stroke and 12″ punch tool diameter. The 16-10-7DD ...

Force: 600 tf

Opening: 500 mm

Stroke: 500 mm

As all our M series hydraulic press, the cylinder is single acting with a lapping liner, chrome plunger and maintenance-free anti wear guide. STRUCTURE AND TABLES This customized hydraulic press consists ...

... information to be taken into account when configuring the press, in order to be able to use the dies in the best possible way. Based on the requested energy, the type of lever mechanism, the press dimensions ...

Force: 800 tf

Working speed: 5 mm/s

... OPEN WORKTOPS mm..1500 - WORKING PLAN mm. 3,000 * 1,600 - CYLINDER PRESS RANGE mm. 1,000 - SPEED CLOSING PRESS mm./sec. 100 - WORKING SPEED PRESS mm./sec.5 - OPENING SPEED PRESS ...

Force: 100 kN

Opening: 50 mm - 1,000 mm

Stroke: 1 mm - 20 mm

SOCOPRESSES

Table length: 1,100 mm - 1,300 mm

Max. pressure: 0 bar - 1 bar

Overall length: 3,300 mm

The BUGA Duo 2612 is the smartest duo oven and membrane press in its class. The oven and the vacuum press are mounted on the same chassis to optimize the space in your workshop and optimize its use. The ...

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining