- Industrial machines and equipment >

- Heat Exchanger and Refrigeration >

- Process evaporator

Process evaporators

... technology, Isımsan offers complex single and multi-stage evaporator systems. These products include e.g. circulating evaporators, thin film evaporators, forced convection evaporators. In ...

Cail & Fletcher Roberts and Kestner evaporator is a rising film type. Installed in multiple effects into the evaporation station this evaporator concentrates the juice from the purification station and ...

Fives Sugar | Bioenergy

Formeco evaporators allow to treat the waste stream separating water from contaminants. The technology is based on boiling the waste water; this water, once distilled, is replaced in the production line, whereas the contaminant, ...

FORMECO S.R.L.

ECOSTILL™ is a self contained evaporator operating without a membrane or a vacuum pump. This is easier to use, more reliable and lower cost than any other competing waste-water treatment technology. ECOSTILL™ can be used ...

... Superior final product quality: lowest holding time, lowest thermal damage. - Running simplicity, continuous and steady process (automatic control). - Long operating time cycle (more than 30 days of non-stop ...

Alimenta Industries S.r.l.

Our MVR evaporators use Mechanical Vapor Recompression (MVR) to recompress all of the vapor from the vapor separator to heat the first stage. Process for MVR Evaporator The evaporated ...

The 420F Pond-based Evaporator is a floating unit designed to increase the evaporation rate on sites where OVERSPRAY/SPRAY DRIFT is an EPA issue. Floating Evaporators – Benefits of the 420F system ...

CoolMist Systems Australia

... production, process heating etc. Other applications such as evaporation of leachate have been identified for this technology. A combination of falling film and forced circulation evaporators has been ...

Swedish Exergy AB

... conventional evaporators. EVAPOR has a small heat transfer surface in relation to its heat transfer capacity, therefore resulting in a compact design with the capability to evaporate far more water per unit area ...

20LT ROTARY EVAPORATOR STRIKE 20 Discover the wide range of rotary evaporators designed for industrial systems and R&D purposes. Completely safe instruments as well as performance optimization. STRIKE ...

Steroglass

... degradation. These features make Economy Evaporators an ideal choice for a range of applications. Our evaporators are designed with various combinations to enhance efficiency and productivity. The ...

... TVR options as appropriate Bucher Unipektin falling vacuum film evaporators are designed to produce high-quality juice concentrates and aroma essences. They typically combine the process steps of; ...

Bucher Unipektin AG

Electrical output: 23,000 W - 174,000 W

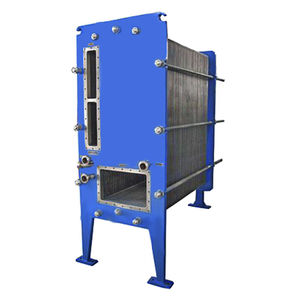

EVA SERIES SHELL&TUBE EVAPORATORS RANGE FROM 20KW TO 1510 KW COOLING CAPACITY IN EVAPTON'S STANDARD CONDITIONS. THE REFRIGERANT SIDE CAN BE MANUFACTURED FROM 1 CIRCUIT TO 4 CIRCUITS. EVA SERIES EVAPORATORS ...

... transfer coefficient is 2-4 times of the tube evaporator), compact structure, convenient disassembly and cleaning, low liquid holding capacity, short time of materials at high temperature, etc., The plate evaporator ...

Electrical output: 3,900 W - 11,000 W

... temperature evaporator is new concentrating equipment developed by our company. It realizes low temperature evaporation through high vacuum degree. There is a spinning roller inside the evaporator. Hot ...

Shanghai Minjie Machinery Co.,Ltd

... evaporation process. The equipment from single-effect to five-effect, production capacity from 1 ton to 10 tons, customers according to material characteristics and production modeling. Main Features The principle ...

Zhejiang Sunny Machinery Technology Co., Ltd.

Koller flake ice machine evaporator is for our customer to assemble flake ice machine themselves. Flake ice: ice thickness 1.5~2.0mm, it is dry and smooth, without edges or corners, which can protect the food very well. Daily ...

Guangzhou Koller R & E Co., Ltd.

Perfect & Innovative • The world's first automatic stopping at process end • High efficiency • Good uniformity • Fast forced air cooling • One-step vessel loading or uploading • Acid waste recycling The World's ...

... Flow Evaporators for Low Temperatures Operate with 1 or 2 compressors. Supplied to operate with 1 compressor, though it is possible to use 2 for energy savings. All that is needed is a simple adaptation to the collectors ...

A Wiped Film Evaporators (WFE) is a thin film evaporator used to separate liquids through their differences in volatility through evaporation. It is a problem solver for difficult applications, such as: ...

... approaches zero and cannot be volatile. The process by which a solution is concentrated by removing part of the solvent by vaporization under boiling conditions is called evaporation. In most cases, the evaporator ...

... With this type of evaporator, due to the built-in mechanical defoamer, the addition of defoaming additives is necessary in only a few exceptional cases. The evaporator operates fully automatically. ...

Uses mechanical vapor compression process for the best energy efficiency Suitable for scaling and fouling fluids Recovers pure water from wastewater Deep vacuum operation allows high quality distillate Limits handling ...

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining