- Production Machines >

- Other Manufacturing Equipment >

- Process screener

Process screeners

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

Weight: 145 kg - 2,130 kg

Opening of the mesh: min 30.0 µm

Screening surface: 0.3 m² - 8.6 m²

Highest screening quality in fine and ultra-fine screening with Tumbler Screening Machines TSM/tsi Allgaier tumbler screening machines have been setting standards in the fine and ultra-fine screening ...

Weight: 75 kg - 510 kg

Opening of the mesh: min 0.5 mm

Screening surface: 0.2 m² - 2.6 m²

Vibration Screening Machines Vibrall High throughput control screening with Vibration Screening Machines Vibrall The Allgaier Vibration Screening Machine Vibrall is used for protective ...

Weight: 140 kg - 695 kg

Screening surface: 0.3 m² - 1.6 m²

Engine power: 0.3 kW - 2.2 kW

Vibration Tumbler Screening Machines VTS Wide range of applications of Vibration Tumbler Screening Machines VTS in dry and wet screening The Allgaier Vibration Tumbler Screening Machines ...

Weight: 90 kg

Capacity: 300 kg/h

Engine power: 0.2 kW

... and artisan markets, these mobile units can be adapted to meet requirements as they change, or fit different points in a process. Their modular design means they can be easily adapted by the user for check screening, ...

Weight: 300 kg

Capacity: 98, 29, 37 kg/h

Engine power: 0.26 kW

... reveal the sieve at the heart of the process, allowing unhindered cleaning access and minimising turnaround times between batches or material changes. Its straightforward interface enables automation of the process, ...

Weight: 100 kg

Capacity: 1,008 kg/h - 1,920 kg/h

Engine power: 0.17 kW

A fully mobile, enclosed, ultrasonic sieve that uses a single 350mm diameter mesh screen to process fine metal powders into flasks/barrels. A non-automated, low volume or research friendly metal powder sieving system. An ...

High containment screener improves your product quality Our Russell Compact Airlock Sieve™ improves your product quality and protects your operators. Its patented TLI (twist, lock and inflate) airlock clamping system ...

... industry. These machines are also ideally suited as screening machines for small manufacturing processes. Due to its compact dimensions, the machine can easily be integrated into any production process.

Weight: 31 t

Engine power: 4 kW

... intelligent remote control to realize long-distance transportation and transfer operations. Screening machine can screen up to 4 types The screening machine can screen up to 4 kinds (three-layer screen) ...

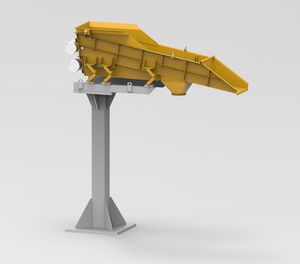

dry screening screenerMSizer

... Giant is considered the world’s largest sizer and can achieve extremely high performance as a single machine. These screening machines are available with different screen decks, allowing for optimal adaptation to individual ...

... Giant is considered the world’s largest sizer and can achieve extremely high performance as a single machine. These screening machines are available with different screen decks, allowing for optimal adaptation to individual ...

Weight: 33,000 kg

Capacity: 200 t/h

Engine power: 110 kVA

Mobile Screen BPE 103 Classtrack - Tracked Hybrid Solution (Diesel-Electrical/Plug IN) Classtrack BPE103 mobile screens provide an efficient solution for material screening with minimal operational costs, ensuring exceptional mobility ...

Boratas Machinery

Weight: 27,000 kg

Capacity: 200 t/h

Engine power: 110 kW

... components and a robust chassis. Tailored Solutions: Available in standard configurations or customizable to meet specific process requirements, Classtrack BPE102 offers various screen mesh options, including standard ...

Boratas Machinery

Weight: 4,000 kg - 12,000 kg

Engine power: 11 kW - 37 kW

Stationary Vibrating Screens BSTE Series Boratas Stationary Vibrating Screens BSTE Series with 2, 3, or 4 decks are used to separate the product according to its sizes. The screens are driven by a shaft system which consists of an ...

Boratas Machinery

... openings (> 50 mm) to remove unwanted items from the product stream or the small openings (< 1 mm) to perform a dewatering process. Compact design to fit the tightest spaces ACVL Series™ horizontal screens have ...

... using our shredding, screening and separation technology to get the best possible sorting of material streams. The first process step is shredding to unbag the material and homogenize the input stream. If needed, ...

Komptech

Screening surface: 4.7 m² - 49 m²

Do you need to screen difficult material that is subject to seasonal, weather, or other changes? Then the BIVITEC e+ is the right choice. As the latest flip flow screen from Binder+Co, it has a frequency transformer in the motor that ...

Binder+Co AG

... design minimizes the wrapping of material Lubo Anti-Wrapping Starscreen (AWS) is a unique machine for material sorting process as it tackles precise size separation and provides highest efficiency in its class. This ...

Weight: 4,200, 4,800, 6,500 kg

Engine power: 11, 15, 18.5 kW

The screening process is just as important as the crushing itself. As the heart of every rock processing plant, screens are used to classify materials in different stages of the crushing process as well ...

Weight: 29 t

Capacity: 450 t/h

... productivity. The K5 has a large range of screening media available ¡ncl. the Bivitec flip flow screen box for very difficult to process materials. The K5 with ¡ts long screen deck is perfect For precisión screening from ...

Engine power: 7.5 kW - 11 kW

SZR series hot ore screen is mainly used for screening operation in metallurgical sintering process, or for materials distribution between sintering machine and cooling equipment. 1.In order to reduce the impact of ...

... along piping. For each MBR treatment it is vital to screen effectively the waste stream before arriving to the membrane process itself. It is well known how screenings can harm or affect the membranes; particularly ...

... The filter elements form a continuous filter belt which is cleaned by a brush at the upper deflection point. The cleaning process is assisted by a series of jets working in proportion to the screenings load. Tines located ...

FSM-Frankenberger GmbH & Co. KG

... the screening technology. As our SPALECK 3D Combi has been developed together with leading recycling companies, this screening machine is tailored perfectly to your requirements and application. Economic wonder: SPALECK ...

Spaleck GmbH & Co. KG

... cater for a wide range of applications, whether it is industries such as aggregate, skip waste management or those wishing to process industrial and demolition waste. Enhanced trommel screening results are achieved by ...

... avoided? No problem – using a screener from Lanner will reliably separate the tramp metals and the further processing will work out fine. The screeners from Lanner can be adjusted individually to fit ...

Weight: 18,000, 12,000, 8,000, 26,000 kg

Maximize your screening process with Polygonmach's state-of-the-art Vibrating Inclined and Horizontal Screens, a key component of our premium range of mobile crushing and screening plants on wheels. Polygonmach, a pioneering ...

... Landfill mining with Doppstadt Rugged and flexible technology for a profitable process. COMPOSTING Composting with Doppstadt: Perfect results at every step of the process. COMMERCIAL WASTE RECYCLING Customized ...

Doppstadt

Screening surface: 4 m²

Two Trough Precision Cleaning and Screening Machine consists of a single section. It is a machine that provides Pre-Cleaning or Sizing. Two Trough Precision Cleaning and Screening Machine performs ...

SRD Machine Agriculture and Construction Industry Trade Limited Company

... options available to best suit your process. - Designed for ease of service and low maintenance. - Available in various widths and lengths – contact our Foundry Specialists to find the shakeout that is best for your ...

... separation of waste materials by screening is becoming increasingly important for both the environment and the economy. This process involves the recycling of different types of materials and the recovery of the associated ...

... processes. They are used to sift wet and fatty floury products coming from filters and/or vibro brushes to extract flour. The process takes place by intensive sieving: the product is “launched” towards the veiling that ...

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining