- Industrial machines and equipment >

- Welding and Assembly >

- Reflow soldering machine

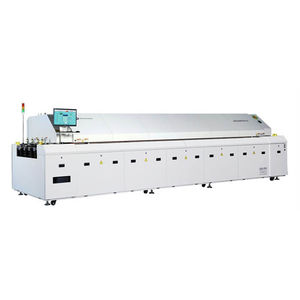

Reflow soldering machines

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

... of low costs. The MRO250 is removable without any problems by means of the small weight and dimensions. The Convection Reflow Solder System has a drawer unit for accepting Printed Circuit Boards on individually adjustable ...

... offers with the reflow solder system the optimal solution for the production of small up to medium series. The reflow oven guarantees an environment-friendly lead-free soldering of highest ...

A compact device used for research. This is the optimum device to use for evaluating the reduction of formic acids. Adding optional specifications gives the Mini even more versatility for a wide range of uses. 1. Formic acid reduction In ...

Compact batch modules suitable for trail and small-scale production. VS2 is equipped with convenient automated load/unload unit. 1. Formic acid reduction In comparison with hydrogen, formic acid has excellent reduction effect at ...

A mass-production unit with two-chambered specifications, allowing for separate cooling and heating. Processing space: 380 mm (W) x 310 mm (D) x 100 mm (H); can handle the mounting of even large pieces of work. 1. Formic acid reduction In ...

... three-phase five-wire (power off UPS protection) 12.Starting Power: 18KW 13.Normal power: 4KW 14.Heating time: 20min 15.Machine control mode: Japan Mitsubishi PLC + Lenovo computer 16.Temperature control range: 350 ...

No. Item Specification 1.Dimension(mm):3200(L)X1250(W)X1650(H) (mm) 2.Color:Gray 3.Weight:1200KG 4Control system 4.1Control mode:Siemens PLC + touch screen dual control software 4.2Automatic Switcher function:automatically sets ...

The new MiniOven 05 is a compact and versatile IR reflow oven suitable for a wide range of SMD components. The device provides enhanced functionalities like integrated air circulation, nitrogen support, and an intuitive ...

... ’s NH-2000A pulsed heat hot bar resistance soldering machine is a fully integrated, reflow soldering machine which utilizes a pulsed heat thermode technology ...

AMADA WELD TECH Inc.

HOTFLOW THREE: the best reflow performance in every respect: Quality. Efficiency. Flexibility. Connectivity. Cleaning. It runs and runs and runs and sets the benchmark for reflow soldering ...

Ersa GmbH

Power: 840 W

Electrically operated (230 V): for safe soldering (no flame), without damaging or annealing the copper pipe. Safe and Easy to use: No flame. No gas. Immediately operational. Easy to carry: comes complete with carrying ...

HOTFLOW THREE: the best reflow performance in every respect: Quality. Efficiency. Flexibility. Connectivity. Cleaning. It runs and runs and runs and sets the benchmark for reflow soldering ...

Kurtz GmbH & Co. KG

... reduction in nitrogen and electrical consumption! This makes our convection reflow oven machines not only the premier reflow soldering machine system ...

Heller Industries

The hot bar Welding, pulse heat units are designed to solder electric components. These systems consist of a reflow head which holds the object and applies pressure and force while the pulse heat power supply then uses ...

... supply - 1 phase / 190-240V, 50/60 Hz Heating in vacuum and inert gas, Power semiconductors on heat sinks, Flip chip reflow, Melting of bumps, High intensity LED attach, Sealing of hermetic packages, Photovoltaic ...

INVACU

Power: 60,000 W

... vacuum reflow oven, hot air nitrogen reflow oven with 10 zones, IGBT modules solder paste reflow ovens, or automotive led vacuum nitrogen reflow ovens, Our vacuum reflow ...

Chengliankaida Technology.co.,LTD

Power: 3,600 W

Highlights The BT301P is ideal for product development, prototypes and small batch production. With the control application based on Android, it is easy to create and save solder profiles. The dynamic control system monitors the size ...

Further improvement in productivity and high functionality • New flux collection unit and cooling mechanism that enables reduction in downtime • Extends maintenance cycle and enables maintenance in a short time period Environmental-conscious • ...

Senju Metal Europe GmbH

... field of convection and vapor phase soldering. The system is based on the reflow convection soldering systems in the Vision series and combines the convection soldering ...

... reel-to-reel system, this machine is ready for in-line production integration. Highlights • Soldering mode: Jet mode/Standard mode • Available solder ball diameter : 40 – 760μm • Recommended soldering ...

Pac Tech – Packaging Technologies GmbH

reflow soldering ovenLyra series

... temperature control system meets the requirements of various soldering processes, It is I.C.T’s crystallization of years technical research and development. Lyra Series Lead-free reflow is high-end ...

Dongguan ICT Technology Co.,Ltd

... Headset Speaker / Main Board PIN Soldering Battery PIN Soldering Charging PIN Soldering Wireless Charging PIN Soldering Other Precision Electronic Assembly Fields

SMD Lead Free Reflow Oven Machine Name: R12 High-end Reflow Oven Model: R12/R12-N Brief: JAGUAR high-end high precision lead-free reflow oven R12 with 12 heating ...

Shenzhen Jaguar Automation Equipment Co., Ltd.

... board can be loaded and shuttled into the chamber for reflow. Low-cost reflow oven best for small batch runs and prototypes. Large window allows the operator to see the board throughout the entire reflow ...

APS Novastar

Power: 6,000 W

... safety device 5. High temperature module (500 degree high temperature) 【technical parameter】 Model: RS220 Welding area: 220*220mm Furnace height: 40mm (other heights are optional) Temperature ...

Beijing Torch SMT Co., Ltd.

Power: 4,500 W

We are a well-known name in the market in offering a wide range of SMT Reflow Oven 5 Zone solder welding QRF320 / QH320. This is equipped with the crawler-type and five temperature area heating systems, ...

... separately. Medium Sized Infrared or Hot Air Reflow Ovens Increase production with these medium sized reflow ovens. Various models from 5KW to 7KW power consumption. Selected models are in stock. Computer ...

Reflow principles: The Reflow oven contains multiple zones, which can be individually controlled for temperature. Generally there are several heating zones followed by one cooling zone. The PCB moves ...

SMT MAX

Power: 1,800 W

Powerful unit for single and series production Board sizes up to 560 x 360 x 80 mm Small footprint Low energy and fluid consumption with 2-chamber design and integrated heat exchanger Touch panel for easy operation, solder automatic, ...

IBL-Löttechnik GmbH

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining