- Robotics - Automation - Industrial IT >

- Industrial Robotics >

- Robotic cell

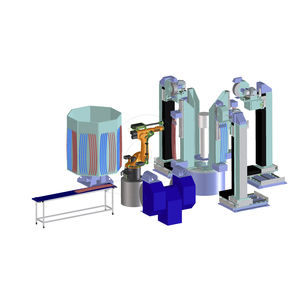

Robotic cells

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

The IBOD System: Intelligent Box Opening Solutions The Intelligent Box Opening Device (IBOD) is an inline, pass-through box opener for automating manual box cutting operations. The IBOD has built-in intelligence, measuring the size ...

... connect to an automated packing system. The high speed of Shibaura Machine SCARA robots has made the development of the packing cell possible. The robot can handle all products weighing less than 10 kilograms due to ...

Looking for a new way to automate soldering? The SolderSmart® Soldering Robot is the ideal solution. Operated via a controller, this quick soldering desktop robot is used for fully automated and reliable processing of single or multi-point ...

... risks associated with part handling during bending are faced by the robot and not by the operator. Press Brake Bending Robotic Cell Includes Following Features And Configuration - Less Waste, Less ...

... Introducing the Robotic Bending Cell ACCURL press brakes can be used in a robotic cell, either completely robotic, or when a robot and an operator can ...

Automation Robotic Bending Solutions, Better Performances, Higher Speed, more Productivity. Introducing the Robotic Bending Cell ACCURL panel bender can be used in ...

ESTUN automatic welding workstation is an excellent choice for welding applications, suitable for high-speed and high-precision welding opérations. Through a variety of robots, welding machines, matching accessories and spécial welding ...

The compact ArcWorld RS & HS cells are flexible, space-saving and reliable options to integrate robotics into welding processes. They are easy to install, operate and relocate.

YASKAWA Europe GmbH

... standard welding cell with two stations, designed for small to midsize objects and with one part positioner in each station. These could be one of the same, or two different positioners. Another important feature is ...

YASKAWA Europe GmbH

Collaborative robotics for easy welding of small series Overview As an alternative or supplement to manual MIG/MAG welding with air-cooled welding equipment, the collaborative Weld4Me robot station offers all the ...

YASKAWA Europe GmbH

... small series and quantities, was realized with this cell plug-and-weld-concept. We support our customers with the easy-to-use operation and clever design of the cell. The PA-c-TT Connect safety cell ...

Panasonic Robot & Welding system solutions

The Pansonic arc welding robot cell PERFORMARC MT (Manual Turntable) is of a modular concept, developed using standard reliable Panasonic components. The Panasonic standard cell is also available in ...

Panasonic Robot & Welding system solutions

The Pansonic arc welding robot cell PerfomArc ET (Electrical Turntable) is of a modular concept, developed using standard reliable Panasonic components. The Panasonic standard cell is available in ...

Panasonic Robot & Welding system solutions

... , just to mention a few. Our robotic cells may be single, double or triple according to the client’s processing needs. • High production rates thanks to the combination of multiple robot units on ...

The most complete and performing solution for flexibility, process and productive capacity. A spreading solution reassuming the concept of Lean Manufacturing and processing efficiency, plus the robot-equipped with a grinding isle and ...

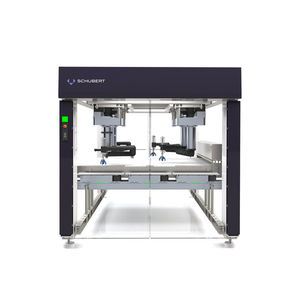

MRC500 dispensing robotic cell The PC controlled mta MRC500 robotic cell is a standard automatic dispensing machine with a working area is of 500x500mm. It can be ...

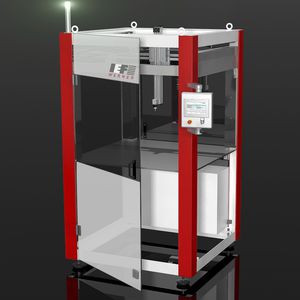

roboCELL The standard cell roboCELL is the starting point for automated production processes. The modular concept allows the adaption to your individual applications. By the use of standardised modules the costs are ...

Machine tending robot cells Available in various different pallet sizes and suitable for all turning and milling machine tool brands. • Flexible and simple setup • Suitable for all turning and milling machine tool ...

Custom solutions for the implementation of robotic systems and cells for technological processes. We offer solutions for machine tending, handling, machining (milling, grinding, polishing), welding, ...

... programming and access to the part to process. Interactive cell management software. Simplified programming and management of multiple functions and parameteres from outside the robotic cell.

MEPSA

Turnkey work cell allowing the integration of "plug and play" integration and of secondary operations from Numalliance or third parties. Main features : Feeding with from coiled material or magazine Full automated ...

The C60 loading robot works in a compact modular processing cell. The precision grinding, lapping and polishing machines are often equipped with it as an interface to plane or plane-parallel machining. The use of pallet ...

Feinschleif-, Läpp- und

Here are some examples of robotic cells and robotic units to weld several parts and components of boilers, water heaters, drums, cylinders, containers, automotive. Masking and blocking ...

Here are some examples of robotic cells for handling and palletizing, integration of production lines and systems, welding and assembly. Custom design and production of clamps and clamping ...

... to increase the overall cell productivity working longer time autonomously and reducing the loading and unloading times. It combines the configurability of DLytePRO500 with a loading mechanism which in turn comprises ...

... oil-based, and aqueous-based solution rinsing, as well as vapor and drying processes. This integration occurs within a matrix cell, efficiently transporting the DLyte PRO500 core through every stage of the process, all ...

... means of which it recognizes the objects to be separated. Also, optionally, it can use near infrared vision (NIR) ROBOT Robotic arm type "Delta" (also known as "Spider" type) with three degrees of freedom of movement ...

... its years of experience in robotics and by close cooperation with KUKA a perfect partner to work with you to automate or robotize your production environment or factory. Whether you're looking for a handling robot, pick and place ...

Welding cell with THDZ (H-TYPE) Positioner. FLEXIBLE Plug & play cell concept with collaborative robot for easier programming. User-friendly concept for first time robot users. SIMPLE AND COMPACT ...

The “Co-Flex” Welding Cell Functions and Advantages: FLEXIBLE Plug & play cell concept with collaborative robot for easier programming. User-friendly concept for first time robot users. SIMPLE AND ...

High Output System for Automotive or General Manufacturing Parts Small system fits in tight spots around the shop. Extremely high output-to-investment ratio. GMAW or GTAW applications Setting the standard in the welding industry ...

This sub-machine assumes the job of picking up products which are fed on a continuously running conveyor belt as controlled by the Vision System and arranging them into product groups. It is equipped for this with two F4 robots which ...

... bending: The TruBend Cell 5000 is the perfect solution for all those who value productive and flexible automation, for the widest possible range of parts. The quality remains consistently high. With the newest series ...

TRUMPF machines & systems

HACO FLEX BEND is a compact robot bending cell which automates the bending of small to medium sized parts in a fast and cost-efficient manner with top precision. Programming is handled completely offline and requires ...

... for auto-programming make these systems an important investment for the integration of future production lines. ROBOTIC PALLETIZING CELLS Palletizing and handling solutions that are highly personalized ...

Metalworking companies are increasingly looking for practical solutions on how to quickly and easily carry out welding tasks. For small quantities, however, automation systems for welding have so far been difficult to implement, from ...

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining