- Robotics - Automation - Industrial IT >

- Industrial Robotics >

- Robotic machining cell

Robotic machining cells

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

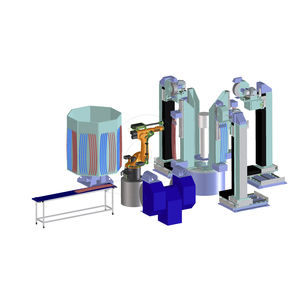

... , just to mention a few. Our robotic cells may be single, double or triple according to the client’s processing needs. • High production rates thanks to the combination of multiple robot units on ...

The most complete and performing solution for flexibility, process and productive capacity. A spreading solution reassuming the concept of Lean Manufacturing and processing efficiency, plus the robot-equipped with a grinding isle and ...

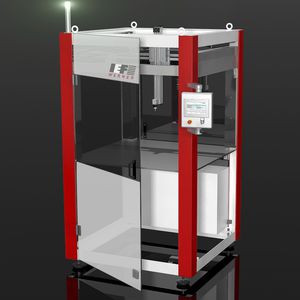

roboCELL The standard cell roboCELL is the starting point for automated production processes. The modular concept allows the adaption to your individual applications. By the use of standardised modules the costs are ...

... C60 loading robot works in a compact modular processing cell. The precision grinding, lapping and polishing machines are often equipped with it as an interface to plane or plane-parallel machining. The ...

... programming and access to the part to process. Interactive cell management software. Simplified programming and management of multiple functions and parameteres from outside the robotic cell.

MEPSA

Machine tending robot cells Available in various different pallet sizes and suitable for all turning and milling machine tool brands. • Flexible and simple setup • Suitable for all turning and ...

... offers a wide range of solutions across a multitude of industries for robotic material and burr removal. Acme has countless robotic deburring machines in the field that are utilizing brush, wheel, and ...

Acme Manufacturing

The FlexTrim Milling by Frimo Group GmbH is a milling robotic cell which feature its ergonomic design and optimal component access. For this specific image, it is positioned ...

Easy operation and robust functionality For milling machines, the "Leonardo Pallet Loader" in combination with the EROWA workpiece palletizing systems is the productive and optimally managed automation solution ...

EROWA

... integrated into new or existing 3-axis, 4-axis and 5-axis numerically controlled machining center of all brands. Thanks to a simple loading concept and an interface without robotic programming, ...

The simplest concept for cnc automation with the largest capacity Medium sized runs 4 pallet positions 70 kg or 165 kg payload Ready for cnc automation? The Pallet-Load Multi is a simple automation solution with the largest possible ...

RoboJob

ADAPTABILITY Customisable work area according to customer and process requirements. AT THE FOREFRONT OF TECHNOLOGY • High speed cutting. Robots 2,000 mm/s. • Programming and offline simulation. Specific software applications. Simple ...

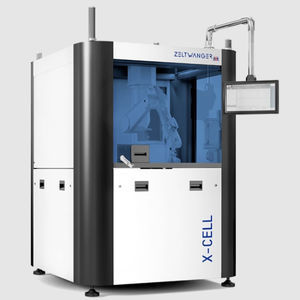

The robot-based machining cell X-CELL LRA from ZELTWANGER completes assembly, machining, laser welding, testing, and marking tasks quickly and reliably. Thanks to ...

... CompactCell with automatic manufacturing cell and a micro precision for the most demanding applications . The CompactCell was designed for micron accuracy multilayer production of small workpieces and allows micro milling ...

... modular robotic cell that comes 95% assembled and is instantly ready for the mounting of a robot. It may be used to install a variety of clamping or fixture instruments, depending on applications. Profeeder ...

Robotic cell equipped with 2 abrasive belt grinding units for welds process. It includes an analog meter that allows the reading and correction of the piece's dimensional differences coming from the welding ...

AUTOPULIT

... precision in productive process > Increase of productivity Example of integrated solution based on standard machines Work cell for automatic execution of BENDING + ENDFORMING thanks to the adoption of an articulated ...

COMPONENT Side members MATERIAL Aluminium TASK Grinding KEY DATA Year of delivery: 2019 Number of systems: 2 Weight of component: up to 30 kg

WMS-engineering Werkzeuge-Maschinen-Systeme GmbH

The 6-axis robotic CNC Machining Cells are industrial systems for machining, drilling, cutting and finishing with 6-axis Kuka robots. 6-axis robots are more and more ...

... Screen We are able to provide maximum customization, concerning both the layout of the cell and the type of robot, we can work with most of the main robotics brands.

CNC ROBOTIC MILLING FOR SCULPTING Shape your ideas with RM-RoboCut3D, the robust 6 interpolated axis robot for three-dimensional milling. Working on polystyrene, wood and stone milling. This is the ...

Ronchini Massimo Srl

Our GRC-R12 robot cell in combination with our G150, G350a and G350 universal machining centers stands for maximum flexibility. Thanks to a wide range of retrofit options, our robot cell ...

GROB-WERKE

... . 7 kg Max Capacity (part + gripper) All-inclusive design, with plug-and-play capabilities to Haas small vertical machining centers, DT/DM series, UMC-350HD, UMC-500, and ST-10 through ST-28 turning centers Interfaces ...

Robotic cells for belt sanding, belt grinding, polishing, scotching, burnishing, brushing deburring or milling of various work pieces. Machine Characteristics The robot cells ...

... FOR XCELERATE ROBOTIC AUTONOMOUS MACHINING SYSTEMS BY CELLRO Automation makes any process more efficient, and the Xcelerate system can improve efficiency and save time to a degree you might not have ...

Vertical and horizontal tapping, with M24 max capacity in aluminium and steel. The XYZ Fast Tap makes light work of: -Reaming. -Chamfering. -Countersinking. -Spot Facing. -Helicoil insertion. -Stud making. -Assembly work – ...

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining