- Industrial machines and equipment >

- Surface Treatment Equipment >

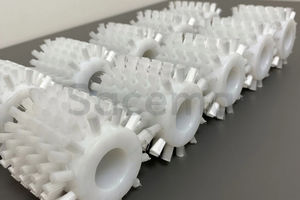

- Roller brush

Roller brushes

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

Diameter: 350 mm

... surface or the processing speed. Depending on your processing requirements, we will select the suitable roller brush together with you. ARKU rotary & roller brushes at a glance Best ...

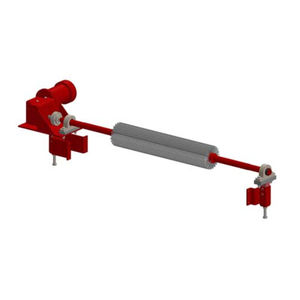

Diameter: 305 mm

Length: 1,067 mm

... cleaning. • Uniquely patterned bristles. Aids in reducing matrial buildup and clogging. • Adjustable Tensioners. Allows easy brush-to-belt adjustment as the bristles wear. • Works on mechanically spliced or vulcanized ...

Shank Ø 3.00 mm Satin-finish wheels made of stacked corundum nylon discs available in 4 different grits: M - F - VF - XF

... Eliminate rootlets from malted grain in malting plants DESIGN •100% stainless steel, food-safe PERFORMANCE • Brush inclination control for efficient brushing • Controlled throughput up to 600kg/hour VERSATILITY ...

THE SUEDING MACHINES WITH MOST EFFECTIVE CONTROL OF THE FABRIC ULTRASOFT with brushes for knits and wovens : produces a very short, dense, perfectly even effect MICROSAND with diamonds for wovens only : gives a finer peach effect To ...

... precision brushing control for both uniform surface finishing and brush wear. Provides superior cleaning performance deep into the strip surface. High-contact density for longer brush roll life and reduced ...

Osborn GmbH

Length: 100 mm

... problems. Supposition for it, is that the roller brush cores are electrodynamically balanced after the mounting of the core according to the required rotation speed and quality G 2.5 which comes up to ...

KULLEN

... in which the abrasive grit is equally distributed • The same results throughout the life of the tool • Easy to handle and mobile due to the light weight construction and compact dimensions • Able to used on dry and ...

TECHNOLIT GmbH

SPECIFICATIONS : BROOM : 18 ft (5.5 m) wide 50/50 poly/wire or full poly Larue cassette bristles or wafer with spacers 46 inches (117 cm) of diameter 8 degrees of tilt Swing angle of 35 degrees Swept path at 35 degrees : 14’9’’ ...

Larue

Diameter: 3 mm - 30 mm

... industrial, logistics and material handling applications. The roller conveyor generally consists of a series of rollers placed on a structure or frame to form a continuous, smooth surface. The rollers ...

The removal of dust and electrostatic charges - we lead the way.. Rotary ostrich-feather roller brushes remove dust from workpiece surfaces in accordance with a simple and reliable principle - due to their intrinsic ...

ABRASIVOS KUMEX

Vegetable and fruit washing plastic roller brush is installed on food processing machine. The applications can be polishing/waxing/cleaning/washing/peeling... Our roller brushes are suitable ...

Anhui Union Brush Industry Co., Ltd.

YILMAZ FIRCA SAN.

When it's required 3 soft brush, as for dusting purposes, synthetic filaments are recommended.

TOSCANA SPAZZOLE

... driven by a geared motor,which has a reversal function too, in order to suit reversing belts. The brush cleaner is designed such that material falls off the brush rather than settle at the bottom of the ...

• Soil, sand, sprout etc. is effectively removed • Spring fingers between rubber discs keep discs clean • Soil and dirt is guided downwards into a box etc. Options • Integrated pintle belt ( see upper picture ) • Customized sub ...

Brush Belt Cleaner Brush belt cleaner is used for material cleaning of the return belt or the lower belt of the unloading pulley. For the cleaning effect of the conveyor belt with uneven surface is better.

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining