- Production Machines >

- Other Manufacturing Equipment >

- Roller mill

Roller mills

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

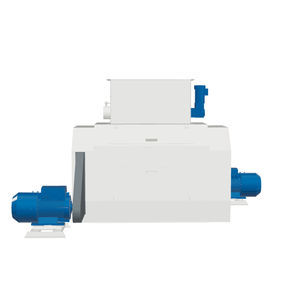

Motor power: 2, 3, 4, 6 kW

Machine weight: 250, 340 kg

The DLP Lump Breaker is an efficient, economic machine specially designed for breaking up friable lumps in bulk materials discharged from silos, bins or hoppers. The DLP Lump Breaker consists of a ...

Rotational speed: 1,410 rpm

Output: 100 g/min

Machine length: 515 mm

Quadrumat Junior: New roller mill for user-friendly lab flour preparation What is it used for? The Brabender Quadrumat Junior is a universal laboratory roller mill with ...

Machine weight: 300 kg

... - Obtaining a total of 4 milling products: - Ground meal - ground meal - semolina bran - bran High efficiency and gentle grinding due to 4-roller system with hardened, profile-ground ...

Output: 6 t/h - 350 t/h

Motor power: 75 kW - 3,300 kW

Machine length: 2,400 mm - 7,200 mm

WTM intelligent vertical mill is dedicated to the high-efficiency dissociation of minerals, providing users with energy-saving, consumption-reducing, quality-enhancing and efficiency-enhancing solutions, realizing maximum ...

Output: 30 t/h - 7,400 t/h

Motor power: 45 kW - 7,000 kW

... surface strong adaptability * Strong process adaptability * Long service life of side baffle * Uniform wear on the roller surface * Uniform particle size * Hydraulic design, easy to control and high system ...

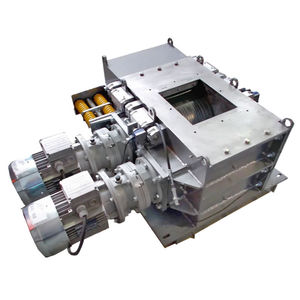

Rotational speed: 428, 360, 348, 270 rpm

Motor power: 1 kW

Machine length: 762, 660, 610, 1,676, 927 mm

... adequately dispersed in conventional high shear mixers. Benefits of Choosing a ROSS Three Roll Mill What does a ROSS Three Roll Mill do? A Three Roll Mill is composed of three ...

Output: 6 t/h

Motor power: 60 kW

... construction and the specially designed roller bearings reduce possible vibrations to a minimum and guarantee a long service life as well as smooth and quiet running. The high-performance flaking roller ...

Single Roller Mill EW-L Our Roller Mills have: A crushing ratio, usually 1:5 ... 1:15, whereby a maximum of 1:30 can be realized. An infinitely adjustable crushing ...

Double Roller Mill WS-L The laboratory version of our two-roller mill is additionally equipped with a feed hopper, a base frame with collecting box and the control system, ...

Output: 600 kg/h - 5,000 kg/h

Motor power: 237, 152 kW

Large output and high production efficiency Large output, more than twice the production efficiency of Raymond mills and jet mills, good product fineness indicators, easy installation of complete sets ...

Rotational speed: 5,050, 1,850, 2,580 rpm

Motor power: 3 kW - 37 kW

... in a mineral factory in Thailand 3t/h A heavy calcium carbonate ball milling and grading + modification production line in a mineral factory in Serbia 750kg/h Barite milling production line of ...

Output: 300 kg/h - 1,400 kg/h

Motor power: 7,500, 30,000 W

... production to fine grinding for the espresso and capsule sector. Design features: • One, two or three stage grinding • Two roller lengths are available • Central belt drive or individual drives • Easily accessible, ...

NEUHAUS NEOTEC

Output: 750 kg/h - 2,500 kg/h

Most advanced grinder for medium capacities and demanding specialty grinds. The newly designed coffee grinder NEOGRIND has been developed specifically for the high demands of filter coffee, pad/pod production (coffee capsules) and fine ...

NEUHAUS NEOTEC

Output: 0 kg/h - 500 kg/h

Motor power: 2,200 W

When it comes to applications with high demands on the particle size distribution, the laboratory grinder LWM 100 is the optimum machine. The fast roll change resulting from the special roll suspension and the precise control via a PLC ...

NEUHAUS NEOTEC

Final grain size: 100 µm - 100 µm

Output: 60,000 kg/h - 480,000 kg/h

Motor power: 2,200, 4,000, 3,000 W

The Waste water Grinder from United Tech Machinery is a high torque, low rotating speed and double shaft grinder under water. It is designed to pulverizing all kinds of solid waste ( clothing, plastic, trash, wood, aluminum can, glass ...

Zibo United Tech Machinery Co., Ltd.

Final grain size: 100 µm

Output: 1,100,000 kg/h - 6,700,000 kg/h

Motor power: 11,000, 7,500, 5,500 W

The Waste water Grinder from United Tech Machinery is a high torque, low rotating speed and double shaft grinder under water. It is designed to pulverizing all kinds of solid waste ( clothing, plastic, trash, wood, aluminum can, glass ...

Zibo United Tech Machinery Co., Ltd.

Final grain size: 1,000 µm

Output: 400,000 kg/h - 1,000,000 kg/h

Motor power: 4,000, 5,500 W

The Waste water Grinder from United Tech Machinery is a high torque, low rotating speed and double shaft grinder under water. It is designed to pulverizing all kinds of solid waste ( clothing, plastic, trash, wood, aluminum can, glass ...

Zibo United Tech Machinery Co., Ltd.

... products. Design: - Roller removal both to the front and to the side possible - Smooth operation, low wear and easy maintenance due to direct drive without chains, belts or gear wheels - One roller ...

Using the KAHL crushing roller mill, legumes, oilseeds, and feed mixtures can be crushed efficiently and with a considerably lower expenditure of energy compared to the hammer mill. The ...

Output: 60 kg/h - 110 kg/h

... (2 pairs of rollers) • 100-3T » 3 passes (3 pairs of rollers) • 100-4T » 4 passes (4 pairs of rollers) Dimension of cutting rollers In addition to the number of ...

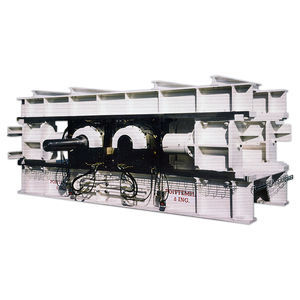

Output: 150 kg/h - 200,000 kg/h

The POITTEMILL pendulum roller mill is a vertical mill that works by compressing the material bed. The pendulums mounted on a star wheel are driven by a vertical shaft. Each pendulum ...

Output: 5 t/h - 500 t/h

DESCRIPTION The Cylinder mill, commonly known as the Roller Press works by crushing the material between two cylinders kept under pressure by a hydraulic system (2 to 10 T/linear cm). This mill ...

Output: 1 t/h - 200 t/h

... Dynamic classifier. This type of separator is usually installed on Pendulum Roller mills but can be used in a pneumatic circuit, alone or combined with a Pulverizer or Ball mill ...

Motor power: 1.5 kW - 45 kW

Machine weight: 1,200 kg - 11,000 kg

... products : Fertilisers, Resins, Salts, etc. Options : Roller cooling Side panel heating Cleaning combs Cleaning scrapers Grinding machine for smooth rollers Rotation controller

Motor power: 200 W

Machine length: 40 cm

Machine width: 26 cm

The MPC mill is ideal for fine trituration and homogenization of ointments, creams, pastes, gels and suspensions: it reduces particles to the optimal size for absorption into the body. The mill features ...

Rotational speed: 220, 330 rpm

Output: 200 kg/h - 600 kg/h

The machine is used separately or coupled with a crusher BLIK to ensure a perfect finition of material for a maximum valorization

Rotational speed: 220, 330 rpm

Output: 800 kg/h - 1,200 kg/h

The machine is used separately or coupled with a crusher BLIK to ensure a perfect finition of material for a maximum valorization

Rotational speed: 0 rpm - 50 rpm

Fully Computerized mills with Automatic mixing of the batch FULLY COMPUTERIZED MILLS WITH AUTOMATIC MIXING OF THE BATCH From manual versions to fully automatic hands-free computerized mills ...

Labtech Engineering Co., Ltd.

... PLACE? After break-out, the operator can safely and ergonomically unload the finished glass sheets manually using unloading rollers or tilt arms. Alternatively, the finished glass sheets can be fed to an automatic unloading ...

Output: 200 kg/h - 120,000 kg/h

With High Pressure Roller Mills products are produced with a precipitous granule distribution. The high pressure roller crusher is also called roller crusher or roller ...

HOSOKAWA ALPINE

... chamber, supported by spherical roller bearings and driven by a fixed speed motor through a planetary gearbox. The capacity of each unit size is relative to the required power input for the intended grind, however, ...

Metso Corporation

Final grain size: 20 µm - 400 µm

Output: 300 kg/h - 10,600 kg/h

Motor power: 15, 37, 55, 75, 132 kW

... continuous for fine grinding of industrial minerals Features Centrifugal ball mill / Roller mill Plant layout and operation similar to conventional roller mills ...

Motor power: 1 kW

Machine width: 550 mm

Machine height: 1,420 mm

... it passes through the rollers below, which differ in size and consequent crushing capacity. Reduced to grains, the product is collected in the special container and sifted through the perforated grid at the exit of ...

... services in grain milling operations. Rugged high-capacity grinding system with high throughput capacity. •The innovative design allows throughput capacities as high as 1000 metric tons per day to ...

Bühler Group

Milling, grinding, kibbling, lump and pre-breaking for a wide range of products The Gericke Nibbler is a coarse grinder and pre-breaker for the size reduction in a broad range of applications. It is used for de-agglomeration, granulation, ...

During metal scrap processing, conveyance systems using augers or steel belts frequently fail to consistently move bushy bundles of metal scrap because the augers and steel belts are unable to grab hold of the stringy wads. This limitation ...

Long wear part life Low operation and maintenance costs Short shutdown for wear part replenishment Up to 20-30% reduced energy consumption Our High Pressure Grinding Rolls are designed with your needs in mind You understand ...

FLSmidth Dorr-Oliver Eimco

Your suggestions for improvement:

A roller mill uses a pair of parallel cylindrical rollers to pulverize material to a desired particle size.

ApplicationsRoller mills have replaced rotary millstones in the food industry. They are also common in pharmaceutical and mining applications.

TechnologiesRoller mills comprise one or more pairs of parallel cylindrical rollers. These can turn at the same or at different speeds.

How to chooseChoice of roller mill will depend on desired output. This is determined by cylinder diameter and speed, as well as the position and dimensions of the grooves cut into each one. The ground product passes through a sieve to ensure proper particle size.

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining