- Production Machines >

- Machine for the electronics industry >

- Rotary magnetron

Rotary magnetrons

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

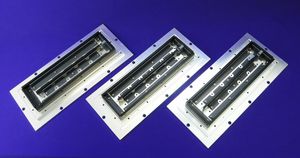

... process at lower power to achieve typical deposition rates. Inherently, Cylindrical Magnetrons can hold up to three times the amount of target material as a planar magnetron with the same spatial area. ...

Angstrom Sciences, Inc.

... performance throughout the lifetime of your magnetron. That is why we provide a comprehensive repair and rebuild service for any emergency or maintenance needs you may encounter on our ONYX® or other magnetron ...

Angstrom Sciences, Inc.

... face generates defects in the growing film; in a rotary magnetron the entire target face is swept clean by a magnet set rotating between 20 and 600 RPM. Angstrom Sciences offer a range ...

Angstrom Sciences, Inc.

... is internationally known for the cutting-edge technology we bring to magnetron sputtering applications. Now, we’ve developed a method for retrofitting your existing MRC style magnetrons with our patented, ...

Angstrom Sciences, Inc.

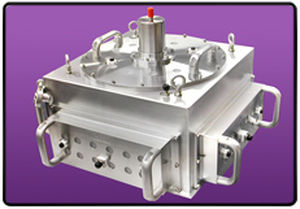

... process. Whether you need custom magnetrons, mounting hardware, flanges, shutter assemblies, gas manifolds, or a complete vacuum chamber, Angstrom Sciences is prepared to assist you. Whether you need custom magnetrons, ...

Angstrom Sciences, Inc.

High Power RF Magnetron Sputtering Cathodes can be successfully implemented in R&D and production applications provided that specific design criteria are incorporated into the construction. Circular ...

Angstrom Sciences, Inc.

... and a simple, easy-to-maintain design. The single-ended configuration reduces the number of rotary and static seals, one of the most common failure modes in rotary cathodes. Our unique water fill and ...

Sputtering Components

... and a simple, easy-to-maintain design. The single-ended configuration reduces the number of rotary and static seals, one of the most common failure modes in rotary cathodes. Our unique water fill and ...

Sputtering Components

... and a simple, easy-to-maintain design. The single-ended configuration reduces the number of rotary and static seals, one of the most common failure modes in rotary cathodes. Our unique water fill and ...

Sputtering Components

The MM is our mid-size external-mount end block. It can handle targets up to 2500 mm (supported) and has a power rating of up to 100 kW DC or 80 kHz MFAC. The MM-Series external-mount end block uses the same patented technology as ...

Sputtering Components

The CM is our most compact external-mount end block. It can handle targets up to 1000 mm and has a power rating of up to 20 kW DC or 80 kHz MFAC. The CM external-mount end block combines high-performance and reliability in a very ...

Sputtering Components

With the Swing CathodeTM end block, the magnet pack swings in a programmable rotary axis that is independent of the rotating target tube, making it an ideal system for display or 3D part coating. The ...

Sputtering Components

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining