- Production Machines >

- Other Manufacturing Equipment >

- Rotor mill

Rotor mills

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

Motor power: 2, 3, 4, 6 kW

Machine weight: 250, 340 kg

The DLP Lump Breaker is an efficient, economic machine specially designed for breaking up friable lumps in bulk materials discharged from silos, bins or hoppers. The DLP Lump Breaker consists of a ...

Rotational speed: 5,000 rpm - 25,000 rpm

Motor power: 100 W

Machine length: 300 mm

... reliably grind very small quantities of samples with most laboratory bench mills. The Tube Mill control Agriculture Solution package, consisting of the Tube Mill control batch mill ...

Rotational speed: 25,000 rpm

... redesigned batch mill grinds hard, brittle, soft and fibrous materials for volumes up to 50 ml. Because samples may be embrittled directly in the grinding chamber; tough, oily and aqueous samples can also be grinded. The ...

Rotational speed: 20,000 rpm

Machine width: 170 mm

Machine height: 350 mm

Batch mill suitable for dry grinding of hard and brittle substances up to 250 ml with a fixed speed of 20.000 rpm. • Double-walled grinding chamber can be cooled with water through two hose adapters • Removable grinding ...

Rotational speed: 300 rpm - 3,000 rpm

Output: 60 kg/h

... . Unique grinding chamber geometry The sample material is comminuted according to the cutting principle of scissors between the cutting edges of the rotor and the fixed knives in ...

Fritsch GmbH - Milling and Sizing

Rotational speed: 2,000 rpm - 14,000 rpm

... many other applications. WORKING PRINCIPLE Fast cutting processes – perfect mixing – representative samples The specially curved knife blades of the PULVERISETTE 11 achieve with up to 56,000 cutting ...

Fritsch GmbH - Milling and Sizing

Rotational speed: 6,000 rpm - 24,000 rpm

Output: 15 kg/h

... The FRITSCH P-14 is the only rotor mill on the market that can be converted into a highly efficient cutting mill in just a few simple steps. This is worthwhile when ...

Fritsch GmbH - Milling and Sizing

Final grain size: 40 µm

Rotational speed: 6,000 rpm - 23,000 rpm

Machine weight: 38 kg

Rotor mills are used for high-speed size reduction of soft to medium-hard as well as temperature-sensitive or fibrous materials. The powerful Ultra Centrifugal Mill ZM 300 provides ...

Retsch GmbH

Rotational speed: 2,000 rpm - 10,000 rpm

The knife mill GRINDOMIX GM 200 is perfectly suited for grinding and homogenizing foodstuff and feedstuff. It accepts sample volumes up to 0.7 liters and homogenizes substances with a high water, oil or fat content as ...

Retsch GmbH

Rotational speed: 3,000 rpm - 10,000 rpm

The Rotor Beater Mill SR 300 is suitable for coarse and fine size reduction, either in batches or continuously. It can process dry, soft, medium-hard, organic and inorganic substances. With its adjustable ...

Retsch GmbH

Final grain size: 5 mm

Rotational speed: 150 rpm

Output: 50 kg/h - 200 kg/h

... granulators in the GSL 180 range feature a staggered 180 mm diameter rotor with widths ranging from 180 to 430 mm. The rotor is directly driven by a geared motor. The low rotor speed ...

ZERMA Europe GmbH & Co. KG

Output: 50 kg/h - 800 kg/h

Motor power: 55, 90, 22 kW

Machine weight: 1,800, 2,500, 900 kg

• Simple adjustment of cutting gap • Choice of discs or segments • Low drive power – High throughput • Innovative efficient design • Wide range of accessories • Easy temperature control The disc pulverizers ...

ZERMA Europe GmbH & Co. KG

Machine length: 860 mm

Machine width: 684 mm

Machine height: 1,712 mm

ZERMA Europe GmbH & Co. KG

The high-speed mill system Zeta® with improved peg grinding system optimizes your production capacity, energy demand and quality. Designed for circulation operation and multi-pass operation, you achieve ...

NETZSCH Grinding & Dispersing

Performance and Efficiency - more than a step ahead General The agitator cooling with the newly-developed Neos grinding system stands for maximum performance, product quality and efficiency. Coupled with the reliable ...

NETZSCH Grinding & Dispersing

... conventional centrifuge rotor, the rotor is equipped with two rotary plates at a specific angle to allow for the proper rotation of the grinding media in the sample vessels to reduce the particle size ...

NETZSCH Grinding & Dispersing

Machine weight: 120, 195 kg

Grinding systems protect your system. With the universally applicable M-Ovas® cutting plate macerator, you can prevent possible damage to your pump caused by impurities. The individually adjustable cutting ...

Machine weight: 170, 260, 320 kg

... impurities. Additionally, the N.Mac® offers the innovative FSIP® concept, enabling complete maintenance and the replacement of the cutting device without removing the entire grinder. This saves both time and money. Depending ...

Machine weight: 220, 780, 360 kg

... control system with reversal of the direction of rotation provides a solution. This allows you to remove blockages in the cutting devices without dismantling the shredder.

Final grain size: 3 µm - 45 µm

Rotational speed: 1,250 rpm - 4,200 rpm

Multi-layer grinding head, strong shearing force and dispersing force It adopts rotor type grinding, multi-layer grinding cutter head, strong shearing force and dispersing force, which can be used for the disintegration ...

Shandong ALPA Powder Technology Co., Ltd.

Output: 10 kg/h - 2,000 kg/h

Remove more than 95% of SO2 and 99% of HCl in exhaust gas It is widely used in municipal waste incineration, hazardous waste incineration, sludge incineration, cement plants, glass plants, steel plants coke ovens and other industries ...

Shandong ALPA Powder Technology Co., Ltd.

Rotational speed: 1,550 rpm - 7,350 rpm

Motor power: 22 kW - 200 kW

The tapered rotor and stator are adopted, and the gap between the rotor and the stator can be adjusted; the powerful vortex flow field, the linear speed of the rotor can reach 120 m/s, ...

Shandong ALPA Powder Technology Co., Ltd.

Rotational speed: 6,000 rpm

Motor power: 2 kW

Machine weight: 68 kg

... use. A turbo rotor can be fitted to the existing shaft. When new the use of the turbo rotor can provide a product size of 97% -212 micron. Turbo rotors can be refurbished and dynamically ...

Volkmann‘s Lump breakers for agglomerates and lumps can easily be added to bag unloading and material pick up stations (e.g. RNT, BBU, RNT-CON). They allow vacuum transport in a closed system free of emissions. They are ...

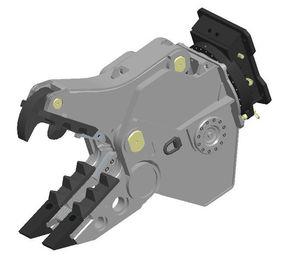

... - 240 mm Max cutting diameter - 45 mm Min. closure time - 3 s** Min. opening time - 1,5 s Hydraulic connections - 3/4” Maximum rotation flow - 25 l/min Maximum rotation pressure ...

INDECO

... length - 240 mm Max cutting diameter - 50 mm Min. closure time - 2 s Min. opening time - 2 s Hydraulic connections - 1” Maximum rotation flow - 30 l/min Maximum rotation ...

INDECO

... length - 240 mm Max cutting diameter - 50 mm Min. closure time - 2 s Min. opening time - 2 s Hydraulic connections - 1” Maximum rotation flow - 30 l/min Maximum rotation ...

INDECO

Output: 50 kg/h - 1,500 kg/h

... granulators are equipped with rotor and stator knives in a crossed manner for scissor like exact cutting action. This machine helps in finer and identical cutting and keeps the heat ...

NEUE HERBOLD Maschinen-u. Anlagenbau GmbH

Output: 150 kg/h - 8,000 kg/h

... and cooler operation. Improved rotor designs eliminate any chance for the rotor knives to lift or loosen during heavy shock loads. The knife bolts attach to a removable and replaceable threaded clamp. ...

NEUE HERBOLD Maschinen-u. Anlagenbau GmbH

Design SMV series granulators are mainly designed for stator as well as rotor knives that are counter angled with one another for producing a true scissors type cutting action. This provides cleaner ...

NEUE HERBOLD Maschinen-u. Anlagenbau GmbH

Do you experience frequent ragging and blocking issues in your pumping process? Mono has the solution to this disruptive time-consuming and costly problem with our easy-fit, de-ragging Muncher package. The Muncher is mounted directly ...

Also, different models are available! IMPORTANT: MACHINE WILL BE BRAND NEW TK Series Chip Crusher is primarily used in manufacturing facilities to efficiently reduce the size of metal chips and turnings, enhancing recycling and ...

Mac 100 granulator shredder For shredding electrical cables (copper and aluminium), plastic and wood. The MAC100 can be used as a pre-shredder. It has 21 flying blades and 4 fixed blades. Supplied with a pre-shredding grid and stainless ...

Final grain size: 1 cm - 3 cm

... feeding of raw rubber bale into the processing line. It may include mechanisms for weighing, metal decting. Rubber Extruding Chopper Machine: This screw etruding rubber bales to die and cut by rotary knives and the ...

Inline and offline colloid mill - MCB The MCB is a mill with stainless steel, perforated plates or corundum grinding elements used for fine grinding and homogenization of liquids, pasty and viscous products, ...

Final grain size: 100 µm - 100 µm

Output: 60,000 kg/h - 480,000 kg/h

Motor power: 2,200, 4,000, 3,000 W

The Waste water Grinder from United Tech Machinery is a high torque, low rotating speed and double shaft grinder under water. It is designed to pulverizing all kinds of solid waste ( clothing, plastic, trash, wood, aluminum can, glass ...

Zibo United Tech Machinery Co., Ltd.

Final grain size: 100 µm

Output: 1,100,000 kg/h - 6,700,000 kg/h

Motor power: 11,000, 7,500, 5,500 W

The Waste water Grinder from United Tech Machinery is a high torque, low rotating speed and double shaft grinder under water. It is designed to pulverizing all kinds of solid waste ( clothing, plastic, trash, wood, aluminum can, glass ...

Zibo United Tech Machinery Co., Ltd.

Final grain size: 1,000 µm

Output: 400,000 kg/h - 1,000,000 kg/h

Motor power: 4,000, 5,500 W

The Waste water Grinder from United Tech Machinery is a high torque, low rotating speed and double shaft grinder under water. It is designed to pulverizing all kinds of solid waste ( clothing, plastic, trash, wood, aluminum can, glass ...

Zibo United Tech Machinery Co., Ltd.

This machine breakes glass bottles for volume reduction.

Rotational speed: 6,650 rpm

... industrial applications. processing a variety of materials; the mill can be equipped with various rotor/stator tooling, depending on the material and the required process; the rotor/stator ...

GlobeCore

DLP rotating pulverizers available for excavators with 18 up to 50t / 39600 up to 110000 lbs operating weight featuring jaw depths of 800, 885 and 950 mm / 31.50, 34.84 and 37.40 in at closing forces of up to 1000, 1100 ...

KINSHOFER

Final grain size: 10,000 µm

Rotational speed: 200 rpm

Output: 0 kg/h - 10,000 kg/h

... deagglomeration of compacted material into smaller particles. The Hanningfield Lump Breaker is designed for the simple deagglomeration of compacted material into smaller particles. Lump breakers can ...

Final grain size: 1 µm - 500 µm

Rotational speed: 12,000 rpm - 18,000 rpm

Output: 5 kg/h

... variator, easy plateau changement, etc. The product is fed at the centre of the mill. Grinding is achieved by impact and by projection between the grinding tools on the rotor, which rotate at a high ...

POITTEMILL / FORPLEX

The BRF dual-rotor universal mill is an evolution of the FNG universal mill. The BRF’s design is based on FORPLEX impact crushers (such as the FNG or FPX models) but is engineered with ...

POITTEMILL / FORPLEX

Output: 200 kg/h - 500 kg/h

... access to the inside and to parts in contact with the product is easy. Usually fitted with a knife rotor, the ELX lumpbreaker can also be used with a blade rotor, more adequate for finer products that ...

POITTEMILL / FORPLEX

Motor power: 15 kW - 250 kW

Machine width: 300 mm - 2,000 mm

Machine weight: 1,500 kg - 20,000 kg

... possible access to wear parts. Hydraulic opening from TFH 800x 1000. It supports the rotor, the frame armouring, the calibration grid or the shredding harrow, depending on the work to be carried out. Grids ...

Output: 300 kg/h - 6,000 kg/h

•Average output 50micron with 90% <100micron. •Custom configuration with storage of different capacities. •Complies with ATEX. APPLICATIONS Grinding granular sugar into powdered sugar for use as an ingredient or as a finished product. ...

TECHNOSILOS

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining