- Environment - Health - Safety >

- Water Treatment >

- Screen

Screens

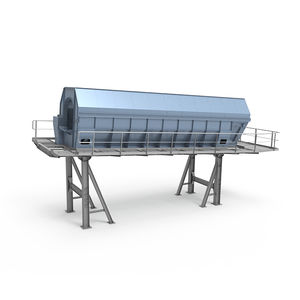

Drum screen plays an important role in separation of various materials. It can be designed to meet various process requirements, which requires different separation sizes and output levels. This equipment features high ...

... municipal wastewater and process water treatment. The Hydro MicroScreen™ is a low-energy, small-footprint rotating belt screen that delivers exceptional solids removal from industrial process water and wastewater. ...

Hydro International

Screens for liquid/solid separation are mainly used in food and beverage industry and waste water treatment. The liquid is sprayed onto the screen by nozzles or flows over the screen by gravity.

Trislot n.v.

A HSF unit consists of a screw screen, a sedimentation tank, a sand extracting screw and an optional grease scraper. Features HSF is designed for a wide range of waste water flow rates with different sedimentation capacities. ...

The step vibrating screen is based on the principle of mechanical vibration. The exciter provides the excitation force to drive the screen plate to vibrate in a circle. The materials are stratified ...

STATIC RUNDOWN SCREEN FILTER for applications such as dewatering processes. It consists of an inlet chamber and a wedge wire curved screen, where the separating process happens. Whilst the liquid ...

Glare Screen Kit Glare screen kit for horizontal downward facing pyranometers mounted on an albedo/net radiation mounting plate. For CMP6-CMP22 and SMP6-SMP22 This glare screen ...

... Most heavy duty machine in it's range Standard heavy duty plate apron feeder and hydraulic folding hopper walls Double deck screen box 2.700 x 1.200 mm (9’ x 4’) 3,24m² screening surface Capacity up to 250 tonnes ...

... that the universal applicability of this abrasive screen with its mesh is of major benefit to their projects. The right abrasive screen for every application Customers purchasing the abrasive screen ...

Product Description Window Screening Coated plastic fiberglass window screening is made of glass fiber by the means of single filament plastic coating process, plain weaving and thermal finalizing. It has the following excellent ...

... entry of sligth quantities of water under certain conditions. Material Aluminum Stainless Steel Bird and insect screens Filters Dampers

With the largest screening surface for its overall length, the Cribus set the standard in the compact class. Its large-diameter drum improves screening performance, and generous spacing between drum and side walls ensures trouble-free ...

HANTSCH SAS

... Technical specifications Robust screen support structure made of tubular members, complete with inspection gangway on both sides and access ladder Under screen collection hopper and over ...

... materials in the desired sizes. The waste coming from the waste conveyor and passing through the tromel screen is directed to the exit conveyor. Our trommel screen, which has a compact design made of ...

... technologies A trommel screen (a.k.a rotary screen) is an automated sorting equipment based on material size. The screen opening on rotary screen strictly controls ...

We usually design the Rotary Trommel Screen according to customer's requests.

... operation and maintenance How does it work? The slurry is fed into the circumference . The fine minerals pass through the screen and go to fine ore hopper.The coarse particles is lifted to the top then be washed ...

... their piping systems do require on occasion in-line filtration. (example pump protection @ stratup) We call these products Screens. A stainless steel mesh filter imbedded in the DN size O-ring. Availbe in many different ...

Fiberglass Plain Insect Screen(YD11) (Recommeded application: residential house,preventing insects,etc) Fiberglass plain insect screen is made of C-glass fiber by the means of filamentship ,plastic-coat ...

... efficient rotation eliminate the need for flocking agent or rinsing water and enhance the quality of the filter cake. The screen baskets, available in different mesh sizes, are very easy to swap out, keeping operating ...

HX Vibrating Screen Processing Capacity: 8-800m³/h Screening Size: 4-100mm Max.Feeding Size: 400mm The HX series vibrating screen is a new type of circular vibrating screen ...

... sifting of the most complicated materials, using the feed motion mechanism with automated load control in the best way. Rotating screen has a large sifting surface that allows to increase the productivity of the sifting.

Description The equipment is used for coarse screening and fine screening of the waste paper pulp, chemical pulp, etc.

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining