- Industrial machines and equipment >

- Surface Treatment >

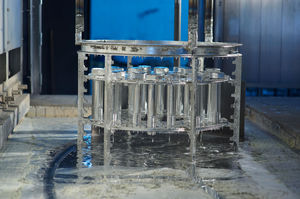

- Small series galvanizing

Small series galvanizing

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

Turning Parts, Metal Parts Manufacturer, Custom CNC machining parts. According to customer requirements, galvanized surface treatment of product raw materials •Material: Steel, Brass, Aluminum, Stainless Steel •Surface Treatment/Finishing: ...

Complementary processing techniques Thanks to the experience developed throughout the years, Fotomeccanica is able to provide additional processing techniques to complete the photo-etching process, such as high-quality galvanic plating ...

FOTOMECCANICA SRL

BIEBER Industrie has been able to grow a 21,000 m2 industrial site, in Drulingen, Alsace France. The reworking of the workshop, providing an adjustable workplace for soldering, assembly and finishing touches, allows the place to accomodate ...

Bieber Industrie

... demands of quality and service lives are crucial. Hot-dip galvanizing is a process where the item for galvanizing is cleaned of grease, oil, mill scale, rust and other impurities. Hot-dip galvanizing ...

We use zinc electroplating to add a zinc coat to materials (Zn and Zn/Ni), which serves as a base layer for further coating, or as a surface finish it gives products a more attractive appearance than in their unfinished state. In any ...

LAKUM

With hot-dip galvanizing, the material to be galvanized is immersed in molten zinc. As a consequence of the mutual diffusion, a layer of differently composed zinc-iron alloy layers forms between the zinc and the steel ...

The ISO 1461 hot dip galvanizing process consists of immersing steel parts in a molten zinc bath (approximately 450 ° C) to produce a protective anti-corrosion coating on the steel. ISO 1461 hot dip galvanizing ...

... machinery and so on. Surface Treatment Our surface treatment ability include : Powder coating Painting Anodizing Galvanizing Chrome Plating Electroplating Polishing Nickel Plating Passivation Enameling

... frequently-employed protection against corrosion. This process is particularly indispensable where lacquer and powder coating would clog small holes or threading. Almost 100 % of the parts to be galvanized are made of ...

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining