- Production Machines >

- Other Manufacturing Equipment >

- Stationary screener

Stationary screeners

Weight: 1,400 kg

Screening surface: 3 m²

Capacity: 50 t/h - 80 t/h

Screen easy to move on site. Your recycling partner. • Made in France • Compact and easy to move • Recycling, calibration, multi-material recovery (wood, earth, gravel, sand, coal, compost, wood, glass, etc.) • Productivity, profitability

Weight: 630 kg

Screening surface: 2.2 m²

Capacity: 10 t/h - 40 t/h

• Made in France • Compact and easy to move • Recycling, multi-material calibration (wood, earth, gravel, sand, coal, compost, wood, glass, etc.) • Productivity, profitability, 3-year warranty

Weight: 900 kg

Screening surface: 2.2 m²

Capacity: 15 t/h - 50 t/h

• Made in France • Compact and easy to move • Recycling, multi-material calibration (wood, earth, gravel, sand, coal, compost, wood, glass, etc.) • Productivity, profitability

Weight: 33,000 kg

Capacity: 200 t/h

Engine power: 110 kVA

Mobile Screen BPE 103 Classtrack - Tracked Hybrid Solution (Diesel-Electrical/Plug IN) Classtrack BPE103 mobile screens provide an efficient solution for material screening with minimal operational costs, ensuring exceptional mobility ...

Boratas Machinery

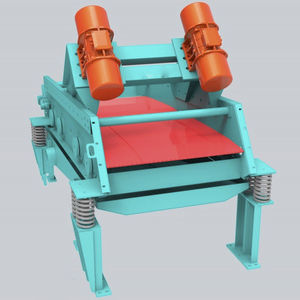

Weight: 6,500 kg - 13,000 kg

Engine power: 18.5 kW - 37 kW

The material is first rinsed and separated in the washing screen using the watering method. It is then separated from the water and sent with the help of conveyors to either a spiral classifier or bucket washer. The watering system ...

Boratas Machinery

Weight: 27,000 kg

Capacity: 200 t/h

Engine power: 110 kW

Mobile Screen BPE 102 Classtrack - Tracked Hybrid Solution (Diesel-Electrical/Plug IN) Classtrack BPE102 mobile screens provide a cost-effective solution for material screening, ensuring exceptional mobility and compactness. Widely ...

Boratas Machinery

Efficient and trouble free operations for all screening application types are provided by the TARNOS vibrating sieves. The material flow speed of the screening feeders can be easily regulated. Pharmaceutical and food processing applications ...

TARNOS

The CS series manufactured by, Tarnos®, is a separator screen. Wherein, it is constructed in a vibration screen that is constructed with ruggedness. In addition it has a screen that continuously vibrates as well as an improved design ...

TARNOS

The CS Series of Separator Screen, manufactured by TARNOS, is specifically designed with a continuous vibrating screen design. This is suitable for use to solve a greater range of tough screening problems more efficiently and economically. Moreover, ...

TARNOS

Screening surface: 2.4 m²

Noise level: 80 dB

Introducing the Hi-E, Elcan’s latest advancement in high “G” force, high volume, linear motion separating and drying rectangular screening machine. This technology works on the principle of resonance; exciters located underneath the screen ...

... The Hi-sifter powder screening machines are offered in both a single or double deck design. The simple design of the machine allows for quick screen mesh cloth changing and minimal down time between runs. The powder screening machines ...

Welcome to the Extraordinary VCR Technology for micronized screening Vibration, is only seen on the screen-wires, not in the machinery. • Non-vibrating structure body • Less vibrating structure enables long lifetime! ...

Screens are indispensable components of the mining plants. Our grizzly screenss designed to have a wide range of applications with high capacities under IMMA warranty. Industrial protected vibromotor, Steel spring wire, Labyrinth ...

Welcome to the Extraordinary VCR Technology for micronized screening Vibration, is only seen on the screen-wires, not in the machinery. • Non-vibrating structure body • Less vibrating structure enables long lifetime! ...

... (L x W) : 2 x 1 m on XYLOCRIBLE 2 M. 4 x 1 m on XYLOCRIBLE 4 M. Rolls driven electrically or hydraulically. Wood screener loading by bucket or wood processor outcome conveyor. Square cam rolls to separate ...

Weight: 1,300 kg

... as a complement. Placed at the output of the screener, the clean logs fall into the receptacle and are directly packaged on pallets. Main Features Rolls driven electrically or hydraulically. Wood screener ...

Engine power: 4.5 kW - 11 kW

CONSTMACH dewatering screens and hydrocyclones are excellent solutions for washing the fine materials with up to 7 mm size. The biggest advantage of choosing Dewatering Screens and hydrocyclones in fine material washing applications is ...

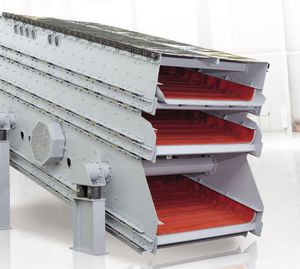

Weight: 16,000 kg - 22,000 kg

Engine power: 18 kW - 30 kW

CONSTMACH Vibrating Screens are highly preferable screening equipments for the purpose of screening all types of material owing to its durable and simple design. Modular structure allows users to change the spare parts and handle the ...

Weight: 175 kg

Screening surface: 0.9 m²

Capacity: 2 t/h - 15 t/h

Type of vehicle: trailer Category: O1 MADE AND DESIGNED IN SLOVAKIA. Return on investment within one year! Only 175 kg! Easy exchange of the meshes. Runs on 220V. Stable construction. Manual handling. Only 175kg, easy ...

dbe.sk

... individual solutions With the world's first LIWELL® screening machines with the Spannwell® principle, we have set standards that shape the current solutions in the industry. The best screening machine ...

The TIBY 1500-500 by Blik is a vibratory screener which can do all types of sorting application. The unit operates automatically which can separate different material in either two or more phase of different granulations. ...

The Rotex® industrial separator with automatic tensioning delivers on-spec product with less rejection of good materials for increased profits. Rotex endures today as the industry standard, thanks to countless applications in the toughest ...

Rotex

The HydraSieve is a simple, highly efficient screen, designed for solid/liquid separation. Thousands of worldwide installations on all types of applications prove its efficiency. Its operation is based on the Coandă effect. This means ...

Metso Outotec EF Series™ screens need fewer parts to perform, increasing reliability and reducing the need for maintenance. Self-synchronized elliptical motion is achieved without gears and timing belts. High capacity design Achieve ...

Metso Corporation

Screening surface: 765 cm²

... of the sieve by ultrasound Design made of chrome-nickel steel in various surface finishes The UFS 765 ultrasonic screening machine was specially developed for screening metal powders when feeding 3D metal printers. ...

AZO Group

Very robust and compact design Accurate regulation of the vibration intensity Highest screening efficiency Very robust and compact design, V (one shaft) and VV (double shaft) series vibrating screens proved to be a very reliable ...

Well-proven, efficient and rugged Septage Receiving Station with integrated screenings press with integrated screenings washing no odour annoyance outside This septage receiving station is used for mechanical treatment of septic sludge. A ...

Huber Technology

Weight: 29,484 kg

Engine power: 93.2 kW

With a 6 ft/1.83 m drum and a hopper that holds 6 cubic yards/4.6 cubic meters, the TR626 makes short work of processing material. Access the drum through removable side panels, drum end or top of the drum. Its 125 hp/93.2 kw John Deere ...

Weight: 27,500 kg

Engine power: 151, 129 kW

The Powerscreen Phoenix 2100 trommel screen is designed to offer unrivalled production throughput and application flexibility. The robust design with optional features such as a heavy duty tipping grid or double deck vibrating grid make ...

Powerscreen

PSR Gyratory Screening Machine Separation on 1 to 3 vertically stacked screen decks. Horizontal gyratory vibration in the feed area ensures rapid product distribution on wide screens. Driven by a low frequency vibrating ...

Vibra Schultheis

AViTEQ-Vibrating Circular motion screens divide into several bulk grain size ranges, seven small amounts of over-or undersize or separate from impurities and foreign matter from the screenings. Vibrating screens are working with directed ...

AViTEQ Vibrationstechnik GmbH

Using resonance, a driving mechanism provides two vibratory movements in which flexible polyurethane mats are expanded and compressed in turns. The material is separated at high acceleration. The dynamically excited screen mats thus remain ...

Dieffenbacher

The ideal system for preparing bulk material is a rotary sifter from Zeppelin Systems. It can be used as a pre-sifter before silos, a final sifter underneath feeding stations and vessels, or as an inline sifter for pressure-sealed operation ...

Weight: 9 t

Screening surface: 16 m²

Engine power: 36 kW

The Primus is an entry-level drum screen. Designed as a tandem central axle trailer, the Primus has 16 m² of effective screening area, and offers a screen length able to handle big jobs. Solid, heavy-duty components like the hydraulic ...

Komptech

Screening surface: 4.7 m² - 49 m²

Do you need to screen difficult material that is subject to seasonal, weather, or other changes? Then the BIVITEC e+ is the right choice. As the latest flip flow screen from Binder+Co, it has a frequency transformer in the motor that ...

Binder+Co AG

Engine power: 52, 53 kW

The Terex® Finlay 595 Hydratrak is a self contained high capacity mobile scalping unit. Designed and constructed to the highest specification, the 595 can withstand the toughest of applications from waste reclamation projects to quarry ...

TEREX Mobile Processing Equipment

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining