- Industrial machines and equipment >

- Surface Treatment >

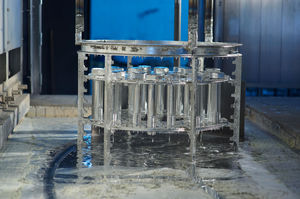

- Steel galvanizing

Steel galvanizing

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

Turning Parts, Metal Parts Manufacturer, Custom CNC machining parts. According to customer requirements, galvanized surface treatment of product raw materials •Material: Steel, Brass, Aluminum, Stainless ...

BIEBER Industrie has been able to grow a 21,000 m2 industrial site, in Drulingen, Alsace France. The reworking of the workshop, providing an adjustable workplace for soldering, assembly and finishing touches, allows the place to accomodate ...

Bieber Industrie

... domain of Steel Structures recognizes the importance of the hot-dip galvanizing which is the most effective treatment for the protection of steel against atmospheric conditions. Thus, ...

... durable and economical corrosion protection for your steel components, we approach the hot-dip galvanizing systematically - from bath to bath and always with the utmost precision. First, the metal ...

... component length / width / height): max. 16,000 mm /2,600 mm / 3,600 mm and a maximum weight of 5,000 kg. Before coating, the steel surfaces undergo meticulous alkaline degreasing, nickel-free zinc phosphating and ...

Glüpker Blechtechnologie GmbH

The highest corrosion protection for your steel. Hot-dip galvanising guarantees perfect all-round protection of your components. In hot-dip galvanising, the pretreated steel parts are immersed in a ...

Collini Holding AG

Hot-Dip Galvanizing or HDG is a process in which zinc bonds to steel at the molecular level to produce a four-layer corrosion-resistant finish. The first three layers are zinc-iron alloy layers that are ...

SUTOR TECHNOLOGY CO., LTD

Widely used in Electricity facilities, Elevator parts

Electrolytic galvanizing of steel parts and products: with a low layer thickness and attractive pricing Multinal Group is the right partner for electrolytic galvanizing of steel ...

... every time. Hot-dip galvanizing is used for agricultural machines, housing equipment, hardware, wind turbines, facades, balconies, stairways, etc. There is no better corrosion protection of iron and steel ...

... applied on Zamak, Steel (Iron), Cast Iron, heat treated Carbon Steel, copper and its alloys; compact coating, with uniform thickness; shiny and semi-shiny look; hardness surface 80 HV; formation ...

With hot-dip galvanizing, the material to be galvanized is immersed in molten zinc. As a consequence of the mutual diffusion, a layer of differently composed zinc-iron alloy layers forms between the zinc and the steel ...

... video) and GALVA 45. THE ADVANTAGES OF CENTRIFUGATION BY GALVA UNION All the corrosion protection qualities of hot-dip galvanizing for small parts. A good quality of finish which very often makes it possible to avoid ...

Mechanical Galvanizing A process where zinc is physically applied to metal substrates, usually steel. Mechanical plating provides a robust surface resistant to corrosion. It utilizes ...

Industrial Metal Finishing

... round steel, pipe, C steel, highway guardrail, traffic sign pole, electric power fittings, Ma Steel parts, light pole, power and telecom tower, solar panel holder, metal ...

... Almost 100 % of the parts to be galvanized are made of iron and steel. Because of its physical chemical properties, zinc is referred to as a "sacrificial metal”, i.e. it protects the steel underneath ...

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining