- Metrology - Laboratory >

- Inspection and Monitoring >

- Surface defect inspection system

Surface defect inspection systems

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

3D SOLDERING INSPECTION ROBOT Automated optical inspection (AOI) for quality control becomes the main issue in all manufacturing processes to ensure effective functioning of the products ...

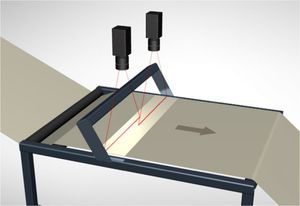

... AI-enhanced Vision The nLine inspection system analyzes a wide variety of products to determine their quality during ongoing production or individual inspection. Three high-speed cameras ...

... AI-enhanced Vision The nLine inspection system analyzes a wide variety of products to determine their quality during ongoing production or individual inspection. Three high-speed cameras ...

... in relation to the board edges, as well as variations in the slot depth. RegChek utilizes BoxChek 7 camera-based, quality inspection software, designed to work with up to 6 cameras/ sensors.

... window. WindowChek then analyzes for defects including folded, torn and wrinkled windows, or contaminants such as scrap, dirt, patch material, etc. that may be trapped between the carton stock and the window.Defects ...

Valco Melton's Coat-Inspekt offers real-time vision inspection for coating processes. An Artificial Intelligence system automatically classifies all errors detected into pre-set categories, facilitating ...

... topography of any surface, revealing microscopic structures that are difficult to detect using traditional inspection techniques. Our proprietary elastomeric tactile sensor technology enables GelSight ...

... our highest resolution handheld surface analysis solution and designed for the most demanding applications, including surface and profile roughness from 0.2 to 20 µm. The GelSight Max ...

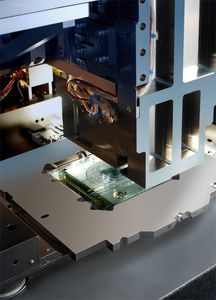

Reticle Defect Inspection Systems for Mask Shop Applications The Teron™ 640e reticle inspection product line advances the development and qualification of leading-edge ...

KLA Corporation

... . The Surface Inspector’s display also makes it easy for engineering and production supervisors to examine the defect. Defect locations can also be recorded, this will ...

Taymer

... Current and an optional 6,000 amps RMS of Alternating Current. This magnetic particle inspection equipment offers magnetisation to find surface and subsurface defects with clearer indications ...

Magnaflux

... contactless real-time inspection of your components. Each component is scanned by high-quality industrial cameras and immediately inspected for faults using our in-house analysis algorithms. If the surface ...

SHS Technologies GmbH

... to prepare and customise each machine for the client’s needs. Maximum speed of extruded product 1200 metres/min. Can control any diameter of extruded product BOW – Optical Print Detection can check for: an absence ...

LASERTECNO S.r.L.

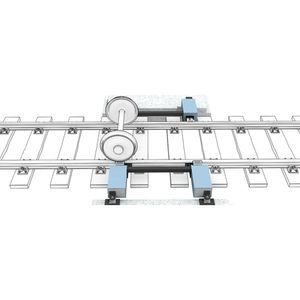

... wheel inspection systems using ultrasonic technology seeks out flaws and cracks by means of the propagation of Rayleigh ultrasonic waves produced electromagnetically on the rolling surface. ...

... sheet surface defect vision inspection equipment is used for inspecting the surface defects of printing sheets , like misprinting , color difference, ...

Estes Engineering Pte, Ltd

... controlled product, image processing software, and algorithms adapted to the required control points. INSPEX OUT is well suited for the inspection of systems or sub-systems ...

... integrating Eddy Current into an automatedEmbedECRangeCutoutreduced system to provide a solution to varied applications such as: • Surface breaking defects detection. • Sub-surface ...

Ether NDE

... cold-rolling mills to monitor the strip surface defects by CCD camera and the control unit. This device helps to improve the production quality and eliminate ...

Automated CrankScan systems allow repeatable inspection of crankshaft journals, fillets, and sidewalls. Stresstech Group´s CrankScan 500 system for crankshaft inspection ...

Stresstech GmbH

Reliable quality control starts as early as in the compounding stage! The system analyzes the particle size distribution in extrusion compounds. Thus the compound quality is checked before production ...

... reflect the defect information of production line surface from time to time. The on-line inspection system for coating surface quality is used to ...

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining