- Production Machines >

- Plastics Processing >

- Thermoplastic injection molding

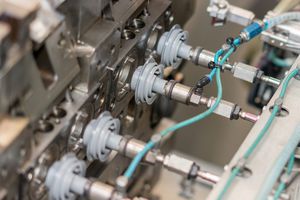

Thermoplastics injection molding

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

... excellent productivity Offers the possibility of very low weight of parts (0.05 gr) and very low wall thickness (0.01 mm) Injection directly into the part by cold block and nozzles (no waste) Very good dimensional reproducibility ...

Injection Moulding The classic manufacturing process for thermoplastic products. By designing the injection tools based on the specific product requirements and by defining the correct ...

Helvoet Rubber & Plastic Technologies B.V.

Injection Moulding The classic manufacturing process for thermoplastic products. By designing the injection tools based on the specific product requirements and by defining the correct ...

Helvoet Rubber & Plastic Technologies B.V.

Injection Moulding The classic manufacturing process for thermoplastic products. By designing the injection tools based on the specific product requirements and by defining the correct ...

Helvoet Rubber & Plastic Technologies B.V.

... temperature-sensitive electrical and electronic components such as plugs, sensors or circuit boards in low-pressure injection molding processes according to customer specifications. In-house production ...

... 0.3 mm can only then be realised with process reliability when the injection moulding machine and the injection mould have been optimally designed for this task. Should the injection ...

... technical moldings called molded plastic parts produced by injection molding, which usually have to withstand high demands. With the help of various manufacturing processes such as 3D ...

In injection molding the plastic filled the form with granules or powder in an injection molding machine, which liquefies the plastic (plasticized). Then it’s injected ...

Name:Customize electric plastic injection mold deep fryer mould mould material:45#,P20,H13,718,2738,NAK80,S136. mould base:LKM,HASCO Cavity:1 or more Runner:cold or hot runner Design software:UG,PROE,CADetc. Plastic ...

... materials used Basic technical thermoplastics: PA, PBT, POM, ABS. High temperature materials: PPA, PPS, etc. Other technical polymers: PEEK, LCP, PSU, etc. Soft materials: Silicone, TPU, TPE, etc. High speed/micro ...

Faiveley Plast

... TECHNOLOGIES Mono-material injection Component overmoulding Bi- and Tri-injection Co-injection Heat and cool (Roctool) Gas injection Injection ...

Adopts plasticizing and injection completely separated, first-in-first-out (FIFO) method. Precise injection volume,minimum injection runner length, and floating-type nozzle ensures excellent ...

3P has a strong know-how in high precision injection moulding of technical plastic gears. Such gears are based high performance and engineering thermoplastics, mainly: PEEK and POM, but also PPA or PPS. ...

3P Produits Plastiques Performants

Custom Plastic Injection Molding Services Our global network delivers precise and efficient production of custom injection molded components, meeting your specific requirements with ...

... materials, injection moulded parts can have custom finishing, polishes, or surface textures. Xometry offers both high-precision tool manufacturing and injection moulding services. Xometry Injection ...

Injection is a mastered technical field, mature, subject to strong international competition. Dedienne MULTIPLASTURGY® Group mobilizes its Research and Development teams to offer its customers differentiating technologies, ...

DEDIENNE MULTIPLASTURGY® GROUP

... structured organisation and rigorous controls guarantee our customers products suited to their needs. Full expertise in injection techniques: multi-materials, copper asbestos working mould casting, etc. 100 presses, ...

MORA

... manufacturing injection moulding tool and producing plastic parts by injection moulding technology. Med-Plast 2000 Ltd developes and manufactures engineering plastic parts. We can support your project ...

Mold Type - Plastic injection mold, overmolding, Interchangeable Mold, insert molding, compression mold, stamping, die casting mold, etc Design software - UG, ProE, AutoCAD, Solidworks, etc Main services ...

ERBIWA MOULD INDUSTRIAL CO.,LTD.

NingBo ChenTe electronics Technologies Co.,Ltd

... customers. In-house mold-making shop ensures your mold quality is under well control. We have 20 sets of injection molding machines. Injection molded parts can be different materials ...

RpProto Co. ltd.

... require high-tonnage injection presses is another benefit that sets us apart in the industry. PRESS SPECS All electric machinery ranging from 310 to 2,200 tons setting the industry standard in all-electric ...

Material: POM, PP, PA, PE, ABS Process: Injection molding Precision machining Extrusion Size: From 50g to 10kg Application: Agricultural machinery General machinery

... type of sealing joint solution by using both ends of pipe(Spigot-end & Socket-end) injection molding, and sealed with the rubber ring. - High Efficiency Injection processing. Joint ...

At CTE we have the technology to manufacture molds and inject components of 1.11 x 0.64 x 0.94 mm with a 0.008 grams weight, 0.04 mm thicknesses and ±0.015 mm of tolerance. All this with a CpK index = 1.3 or higher, since, otherwise, ...

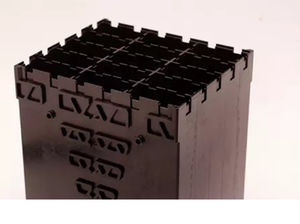

Tower packing is deployed in wastewater and exhaust air treatment, for example. This includes tower packing made of special plastics and high-performance plastics such as: PEEK PFA PVC PVC-C PVDF ETFE E-CTFE

RAUSCHERT

At DLR Elastomer, we pride ourselves on offering a bespoke custom rubber moulding service, understanding application requirements, designing the parts, tooling & process to deliver the product to the clients’ exact and demanding performance ...

DLR Elastomer Engineering Ltd

The main facility is injection molding machine, which brand is Lijing from Hongkong.The injection molding tonnage is 50 t -250 t.

... plastic injection parts rather invariably leads to high investment in tooling which may impact your project viability from the start. That is why we offer very low tooling costs to our customers, while keeping high competitiveness ...

A.G.C. BUSINESS CONSULTING S.A.

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining