- Machine-tools >

- Cutting Tool >

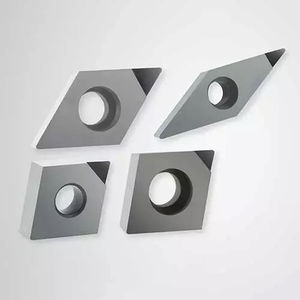

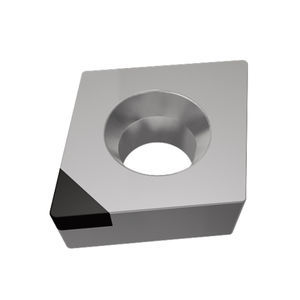

- Tungsten carbide cutting insert

Tungsten carbide cutting inserts

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

SPMG Type Carbide Insert Suitable for machining: steel / stainless steel / cast iron Grade: WT5025

APMT1135PDR / APMT1640PDR Suitable for :steel / stainless steel / cast iron Grade: WT3010 WT3015 WT5025

RPMW Type Carbide Inserts Suitable for machining: Hardened steel / Cold cast iron / Stainless steel Grade: WT3010 WT5025

... High-strength edge design with double rake angle chip-breaker ensures good impact resistance and a certain sharpness of the insert at the same time. The best chip breaking range is Fn: 0.3-0.50mm/r; The primary ...

Stainless steel finishing chip-breaker: The rake angle and edge inclination angle are designed for the processing characteristics of stainless steel materials, and the blade edge is sharp. Small chip resistance, excellent chip breaking ...

Binderless SUMIDIA Grade The binderless PCD grade NPD10 is our first recommendation for high-precision machining of tungsten carbide as well as hard and brittle materials. Excellent ...

... productivity with metal cutting saw tip blanks. Our range of cemented carbide and cermet blanks cut ferrous, nonferrous, and nickel-based alloys. Metal cutting saw tip blanks are designed ...

... Milling Carbide Inserts: Versatile and Cost-Effective Milling SN-type Milling Carbide Inserts stand out for their geometric efficiency and adaptability in various ...

Heikenei

Suitable Materials for PCD Symbol of Cutting Edge and Cutting Direction Ultra diameter. best quality of surface. Low silicon aluminium processing(electronic products) Titanium alloy processing

... depth of cuts and high speed associated with machining of hardened ferrous materials. CBN cutting tools offer excellent heat dissipation and wear resistance. Cutting tool geometries can be prepared ...

It is mainly used for milling engines, high-efficiency processing of Tungsten carbide rolls, and other high-efficiency and high-quality processing. LEADING POSITION We're in the leading position, is the well-known brand ...

... industry standardsAnd, we could produce as per customized Tungsten carbide tips.

Your suggestions for improvement:

the best suppliers

Subscribe to our newsletter

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining