- Packing - Handling - Logistics >

- Conveying >

- Vibrating conveyor

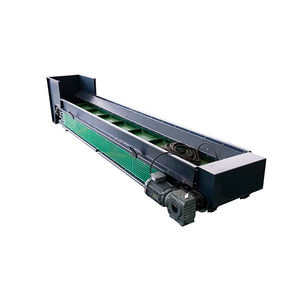

Vibrating conveyors

Product introduction The vibration conveyor uses the vibration of the trough to quickly transport the material in the trough from the inlet to the outlet, which can be used to transport ...

Effective width: 450 mm

... guiding curves in wear-resistant steel Planned options on the structure Ant-wear coffer coffer waranty 10 years Back of conveyor Sprockets Type Fixation clamps No additional clamps Receiving hopper YES-Length: ...

Effective width: 1,600 mm

A mechanical conveyor operating at natural frequency takes the product from the Pre-Breaker Unit and transfers the product to the Kibbling Unit. The unit comprises: Stainless steel trough Variable speed drive unit The ...

... or back-up segment. Likewise, the drive is suitable for hopper systems with lighter mass-produced parts. - Linear vibration drives for rail lengths up to 2000 mm - Matching control and regulation devices - Depending ...

... while it conveys to optimize operations in packaging of bulk materials or production of molded products. Use of gentle vibration ensures efficient removal of voids and air pockets in containers, molds or packaging without ...

... efficiency and as a main vibrating cooler creator in china. We also provided wheel mounted mobile crushing and screening plant, vibrating board, blast turn-face vibrating screen etc.

Features: Speeds in excess of 600 parts per minute Bowl sizes range from 6" to 36" I.D. Ten different sizes available Constructed of 11-gauge stainless steel Custom tooled by experienced craftsmen Variety of placement devices ...

... Batching unit by vibrating channels Batching system by set of vibrating channels with main conveyance group Filling machine with vibrating channel for small cans or bags with weighing ...

... symmetrical two same types and specification of the vibration exciter motor or synchronous reverse operation, the vibrating through the vibration body, motor or exciter base transferred ...

Xinxiang Weiliang Sieving Machinery

SINEX vibrating conveyors on leaf springs are equipment of great lengths (up to 25 meters in one part depending on the design)trl_1_sinex Depending on the size of the conveyor, the ...

Designed to remove small dirt particles out of the ‘dry’ stage of the processing line. Our Knocker Conveyor removes fines, like insects and sand, by means of belt knockers underneath the perforated belt. As the belt shakes, ...

Urethane vibratory bowls are screen mats made from urethane that is punched for the material being processed. Made from a soft urethane they can be used as a final filter on urethane vibratory bowls and are commonly found in mining industries ...

Vibrating conveyor for the welding parts structure, the body material used in all high-quality steel plate, the X-ray inspection, welding without defects, strong, resistant to vibration, no welding cracks ...

Effective width: 60 in

... Lippmann magnet conveyors are perfect for any application where a magnet is required. Set-up specifically for recycling applications with the conveyor featuring a self-cleaning magnetic, reinforced belting, ...

Vibration conveyor and transport belts automatically transfer the finished product to the subsequent plant after cooking and cooling.

... ancillary equipment to suit individual customer requirements: Infeed/discharge conveyors Screw conveyors S+S metal detectors Overband magnets Drum magnets Vibrating screens Cyclones Bagging ...

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining