- Products

- Inspection table

- -4H- JENA engineering GmbH

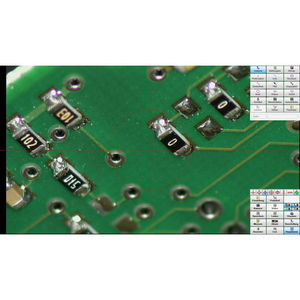

Inspection table VT series

Add to favorites

Compare this product

Description

The VT- and IT-inspection table series are used for the precise adjustment of specimens in the optical inspection.

Exact positioning and reproducible workflows ensure an increase of productivity at testing and inspection tasks.

Applications:

inspection of flat parts

extension to existing optical systems by positioning tables

inspection, repair and audit works with reproducible workflows

Advantages:

compact dimensioned inspection and translation tables

flat construction and precise linear guidance system

for incident and transmitted light applications

ESD pad with ground connection for the safe handling of PCBs and electronic components

precise positioning of specimens by threaded spindle

through the flexible modular system the table can easily be adapted to the individual customer-specific requirements

Options:

x-/y-axis by clamping screws in any position lockable or with rough/fine adjustment by threaded spindle

ESD pad with ground connection for incident light applications

glass shelf for transmitted light applications

all tables can be equipped by a stand column

Catalogs

No catalogs are available for this product.

See all of -4H- JENA engineering GmbH‘s catalogsOther -4H- JENA engineering GmbH products

OPTICAL METROLOGY

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.