- Products

- Catalogs

- News & Trends

- Exhibitions

Planning software IQCmonitoringmeasurementquality

Add to favorites

Compare this product

Characteristics

- Function

- planning, monitoring, measurement, quality, control, reporting, calculation, inspection, data collection, sampling, CMMS

- Applications

- medical

- Type

- automated

Description

Streamline IQC for mission critical products (aerospace, medical, life sciences, defense, space etc.). Automate inspection planning, sample size calculation, lot-switching (reduced, tightened, skip-lot), measurement data collection, and supplier performance reporting. Eliminate paper records and simplify compliance. Save hundreds of hours time, reduce errors, and free-up inspection capacity.

EFFICIENCY & COST SAVINGS

“This software is amazing what it can do!! The efficiency and cost effectiveness alone was a big win for us. This software provides less paper work, less errors, more quality, monitoring capabilities, spec. requirements, QC Plans, Inspection Plans, Supplier Dashboards, all of this and so much more. And did I mention the money it saved in labor...outstanding!!! Altogether a winning situation.”

HOW IT WORKS

1. Inspection Plans

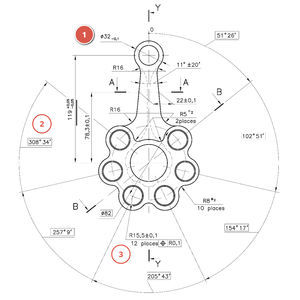

Easily balloon drawings and extract critical (or all) dimensions to create control plans. Add inspection methods, AQL-based sampling rules, and approved suppliers to each plan. Version control the inspection plans and track change history.

2. Sampling & Inspections

Enter incoming lot size and enjoy automated sample size calculations. Eliminate AQL table look-up errors. Record attribute (Pass/Fail) and variable (Numeric) data from keyboard, digital gages, CMMs and Vision Systems. Save hours of data-entry time and eliminate errors.

3. Lot Switching

Make a lot-switching decision (Normal, Reduced, Tightened) based on historical performance of Part & Supplier. Enjoy fully automated sample-size recalculation with switching. Easily identify candidate parts to move to Dock-to-Stock programs .

Related Searches

- Automation software solution

- Analysis software solution

- Process software solution

- Control software solution

- Real-time software solution

- Monitoring software solution

- Measurement software

- Quality software

- Automated software

- Machine software

- Engineering software

- Test software

- EDM software

- Creation software

- Reporting software solution

- Planning software

- Safety software

- Calculation software

- Inspection software

- Flow software

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.