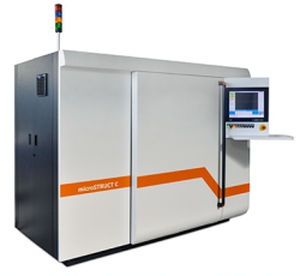

Laser welding machine microWELD™automaticcompact

Add to favorites

Compare this product

Characteristics

- Technique

- laser

- Operational mode

- automatic

- Other characteristics

- compact

Description

The manufacturing of medical instruments and implants is characterized by smaller and smaller structures as well as the demand for highest precision in terms of surface quality, absence of burr, and materials residues. While established fabrication technologies increasingly face their limits, laser micromachining provides optimum preconditions for the required quality and precision since machining is accomplished in a contactless fashion.

Therefore the company developed their new laser system microWELDTM for welding metals, which enables to weld airtight for instance NIOB, titan and different steels. It is possible to precisely adjust the geometry of the weld by variation of the lasers` parameters and hence to weld smallest components with a very small heat-effected zone. For instance, seam widths of 0,3mm and seam depths smaller than 0,1mm can be achieved independent of the material.

Catalogs

No catalogs are available for this product.

See all of 3D Micromac‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.