CNC drilling machine Helical Drilling Opticslaser

Add to favorites

Compare this product

Characteristics

- Type

- CNC

- Other characteristics

- laser

Description

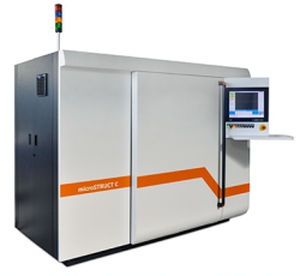

Laser drilling of micro holes of extraordinary quality and high aspect ratio is accomplished by laser-induced plasma erosion and requires a dedicated conditioning of the laser beam. In order to generate holes of high circularity and defined taper in metal sheets of up to 2 mm thickness, the beam needs to become conditioned using dedicated helical drilling optics. Within this drilling head, the beam profile is optimized such that the laser beam is rotating in itself and impingement angle as well as diameter of rotation trajectory onto the work piece can be fully controlled.

Catalogs

No catalogs are available for this product.

See all of 3D Micromac‘s catalogsRelated Searches

- CNC machining center

- Vertical CNC machining center

- 3-axis CNC machining center

- Drilling machine

- CNC drilling machine

- Universal CNC machining center

- Laser CNC machining center

- Micro-machining machine

- Laser micro-machining machine

- Laser drilling machine

- Cutting micro-machining machine

- Drilling micro-machining machine

- Metal micro-machining machine

- Welding micro-machining machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.