Process monitoring system DMP real-time

Add to favorites

Compare this product

Characteristics

- Applications

- process

- Other characteristics

- real-time

Description

REAL-TIME PROCESS MONITORING FOR INFORMED DECISIONS ON PRODUCT QUALITY

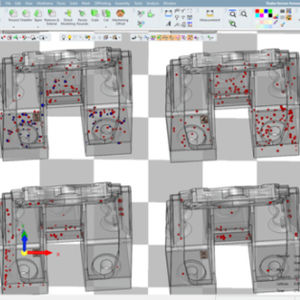

DMP Monitoring is a toolset for DMP Flex 350, DMP Factory 350 and ProX DMP 320 metal printers that allows customers to see, analyze, understand and fine-tune their DMP process beyond levels ever possible before. This enables customers to achieve higher quality output through better DMLS process quality monitoring and assurance. The efficient and intuitive DMP Monitoring Software User Interface is developed based on the experience of printing 500,000 metal parts year-over-year in our metal printing facilities in Leuven, Belgium and Denver, USA.

Automate the data analysis with DMP Inspection

Wealth of process data for non-destructive analysis and understanding of metal 3d printing build quality, accelerated process parameter optimization and enhanced understanding of process results.

Real time build analysis

The DMP Monitoring toolset for enhanced quality control includes real time process monitoring, synchronized images of the melt pool and powder bed, synchronized images of real time and archived jobs for comparison and a toolset for analyzing the magnitude of a subject area. DMP Monitoring enables the user to fully understand and control the process allowing the user to take corrective action to minimize the inherent side effects of all metal 3D printing technologies such as spatter and lump formation to significantly improve part quality.

VIDEO

Catalogs

Exhibitions

Meet this supplier at the following exhibition(s):

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.