- Products

- Filter diaphragm

- 3P Produits Plastiques Performants

Air filtration membrane Permeon®PTFE

Add to favorites

Compare this product

Characteristics

- Type

- air filtration

- Material

- PTFE

Description

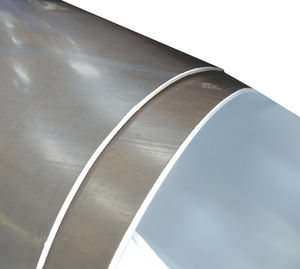

Venting or breathing membranes are required to protect an enclosed area from condensation and humidity. Due to temperature variations, humidity and condensation can appear and deteriorate the components. To allow humidity and pressure equilibrium between inner and outer space, while preventing contamination by dust or liquid, breathing membranes and venting membranes are the best solutions.

With 50 years experience in PTFE processes, 3P has developped its own technology for integrated venting membranes and pastilles: Permeon®.

Permeon® is a 100% PTFE venting solution, showing high thermal and chemical stability.

It is based on sintered porous PTFE. Compared to stretched ePTFE, it offers

- high mechanical properties: resistance to high pressure projection (Kärcher test), no need for plastic cap (that induce low venting surface)

- high temperature resistance: no soldering, no adhesive needed.

Machined parts are custom designed to fit any system. Seamless pastilles and membranes are no constraints for the design of the whole system.

This unique design allows:

- plug-in assembly: no support or cap, simple assembly, simple system preparation for global cost gains

- seamless integration: no space required around the assembly

3P uses in-house test benches to select the right venting properties, depending on flow rate, Water entry pressure (WEP) and/or pore size.

Each solution is developped for the real conditions.

Other 3P Produits Plastiques Performants products

PTFE parts

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.