- Packing - Handling - Logistics

- Packing and Packaging

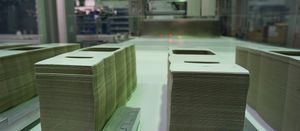

- Layer palletizer

- A+F Automation + Fördertechnik GmbH

Robotic palletizer 350Q serieslayercratetray

Add to favorites

Compare this product

Characteristics

- Type

- robotic, layer

- Product applications

- crate, tray, handling, conveying

- Other characteristics

- modular

- Throughput

400 p/h

- Pallet weight

180 kg

(396.83 lb)

Description

The governing criteria for selecting the optimum palletizing system depend upon individual customers’ requirements. On that principle, A+F offers both robot palletizers and conventional palletizers in layerplate forms, well integrated into the production environment.

A+F‘s conventional palletizers are particularly suitable both for high speed applications and when handling heavy weights, at speeds of up to 400 layers/h. The space-saving palletizers require only minimum floor space and provide a simple, but reliable solution with minimal servicing requirements.

Robot palletizers focus on extremely high flexibility. With a single gripper system all products, layer sheets and pallet handling can be processed from up to four different production lines simultaneously. A+F‘s robot palletizers operate at the highest levels of quality and flexibility and ensure the maintenance effort and costs are kept to a minimum.

A+F’s scope of supply can comprise all line elements, such as tray/crate conveying from the packing machine, empty pallet magazine/supply and full pallet conveying to either a high bay warehouse or the final dispatch point. For total tracking of goods, a data exchange interface with other storage identification systems can be provided.

All A+F‘s palletizers are of modular design and construction and rely on long-term expertise and technology proven in many diverse industries.

VIDEO

Catalogs

Other A+F Automation + Fördertechnik GmbH products

Machines

Related Searches

- Palletizer

- Shrink wrapper

- Automatic sleeve wrapping machine

- Case packer

- Layer palletizer

- Robotic palletizer

- Automatic case packer

- Case palletizer

- Horizontal case packer

- Tray erector

- Carton case packer

- Modular palletizer

- Automatic tray erector

- Tray palletizer

- Handling palletizer

- Sleeving machine

- Automatic sleeving machine

- Food case packer

- Case case packer

- Double shrink wrapping machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.