- Packing - Handling - Logistics

- Conveying

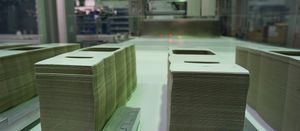

- Roller conveyor

- A+F Automation + Fördertechnik GmbH

Roller conveyor horizontaltransportwork

Add to favorites

Compare this product

Characteristics

- Technology

- roller

- Form

- horizontal

- Function

- transport, work, feeding

- Construction

- wide

- Drive mechanism

- electric drive

- Transported product

- carton

- Applications

- process

- Maximum load

100 kg

(220.462 lb)- Bulk throughput

18,000 kg/h

(39,683.207 lb/h)

Description

The system planning includes consulting work and engineering of the production lines as well as providing the final offer.

The support includes extensive layout drawings as well as calculation of the machine speed and output, sleeving concepts, carton layouts, palletizing patterns, layer inserts and product sheets.

The extensive A+F product range includes carton-stack-transport-system, gripper for the stacks (for palletizing and for the feeding oft he folder gluer hoppers) robot and conventional layer palletizers and conveying systems for the transport oft he stacks, cases and pallets.

Experienced project managers are assigned to be the key contact for the customer during the lifetime of the project. He will manage all dates, sample materials and final test of the equipment amongst other things.

All A+F equipment is CE-standard, alternativ the entire

Equipment can be delivered with parts with UL-certifiicate.

Key system components will be commissioned at A+F and an acceptance test is done with the customer.

The installation and commissioning at the customers site will be executed by our specialist service personnel and will be finished with a SAT.

The A + F systems are characterized by a high degree of flexibility in the entire system and short cange-over times. This allows the customer to process a wide variety of different blanks.

The complete systems can be equipped with a free line pre-selection.

Catalogs

No catalogs are available for this product.

See all of A+F Automation + Fördertechnik GmbH‘s catalogsOther A+F Automation + Fördertechnik GmbH products

Machines

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.