- Production Machines

- Other Manufacturing Equipment

- Steel lost wax casting

- A.G.C. BUSINESS CONSULTING S.A.

- Products

- Catalogs

- News & Trends

- Exhibitions

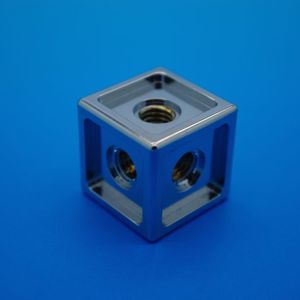

Steel lost wax casting

Add to favorites

Compare this product

Characteristics

- Material

- steel

Description

Our capacities in lost wax investment casting

Parts from hundredth grams to 100kg

Available materials :

Carbon steels

Stainless Steel

Aluminium and non ferrous metals

Surface treatment solutions

3-4 axis machining centers

Custom packing

What is low wax investment casting?

Lost wax casting is a process that enables to produce metal parts by pouring liquid metals into molds that are created around a wax made reference part.

Different stages of lost wax casting :

Manufacturing of the wax pattern part

Assembly of wax patterns trees, hanged from supports

Coating of the trees with thick layer of refractory material (investment material) in order to create several “molds”

Wax melting and removing from the refractory material in order to create molds cavities

Pouring of melted metal in heated molds

« Molds » destruction and recovery of the metal parts

Metal parts are separated by cutting from the parts trees.

Parts finishing (sand blasting, deburing, machining, treatements)

Other A.G.C. BUSINESS CONSULTING S.A. products

Metal

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.