- Hydraulics - Pneumatics

- Filter and Separator

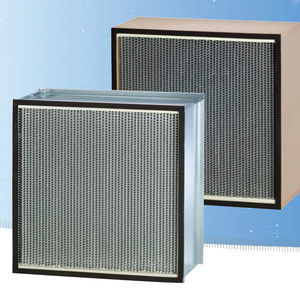

- Panel filter

- AAF International

Air filter MEGAcel® Ipanelfor the pharmaceutical industrypleated

Add to favorites

Compare this product

Characteristics

- Designed for

- air

- Filtration element

- panel

- Applications

- for the pharmaceutical industry

- Other characteristics

- pleated, high-efficiency, anti-corrosion, HEPA

- Operating pressure

5,000 Pa

(0.725 psi)- Filtration size

0.3 µm

Description

Product Overview

Lowest initial resistance – Up to 50% lower

AAF’s high tensile strength ePTFE media is up to 8 times stronger than micro fiberglass

Highly resistant to corrosive environments (acids, alkalis, and organic substances)

Negligible off-gassing properties (boron, sodium, potassium, silicon)

Withstands pressure up to 20 in. w.g. (5,000 Pa)

99.99% minimum efficiency at 0.3 μm

Typical Applications

Commercial Buildings

Microelectronics

Healthcare

Pharmaceutical

Energy Conservation=Energy Savings

AAF ePTFE pleat pack resistance is up to 50% lower than conventional micro fiberglass media, a significant factor contributing to a great reduction in fan energy consumption. AAF ePTFE membrane media, combined with tapered aluminum separators, optimizes pleat pack resistance. With a reduction in fan energy consumption, overall energy savings can be realized.

Perfect Filter Media

Compared with micro fiberglass media, ePTFE membrane media provides superior benefits, including inert chemical properties, more uniform fiber distribution, smaller fiber diameters, and smaller pore size. As a result, reduced resistance and higher filtration performance provide substantial energy savings.

VIDEO

Catalogs

Related Searches

- Filter cartridge

- Industrial filter cartridge

- Pressure separator filter

- Filter for industrial applications

- General purpose filter cartridge

- Plastic filter cartridge

- Panel pre-filter

- Filter element

- Compact separator filter

- Dust pre-filter

- Process separator filter

- Pleated pre-filter

- High-efficiency pre-filter

- Aluminium filter

- Bag filter

- Membrane filter cartridge

- Air filter cartridge

- Particulate separator filter

- Gas filter element

- Activated carbon pre-filter

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.