- Hydraulics - Pneumatics

- Valve

- Mass flow regulator

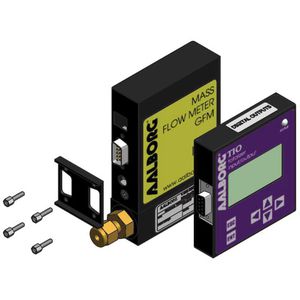

- Aalborg Instruments

Thermal mass flow controller DFC for gasdigitalanalog

Add to favorites

Compare this product

Characteristics

- Technology

- thermal mass

- Fluid

- for gas

- Other characteristics

- digital, analog, precision, compact, stainless steel, for OEM, for low flow rates, industrial, cost-effective

- Flow rate

Max.: 100 l/min

(26.41721 us gal/min)Min.: 0 l/min

(0 us gal/min)- Pressure

1,015.3 psi

(1,015.3 psi)Max.: 1,000 psi

Min.: 15 psi

Description

DFC programmable thermal mass flow controller with digital signal processing

Design Features

odigital and analog modes operate

oprogrammable flow configurations

oavailable flow ranges starting from 0 to 10 sccm up to 0 to 100 slpm

omaximum pressure of 1000 psig (70 bars)

omulti-drop capability of up to 256 units

ostores calibration data for up to 10 gases

ototalizer indicates total gas quantity

oalarm limits for high and low gas flow

oconversion factors for up to 256 gases

oauto tune function for optimum control response

oself diagnostic tests

DFC digital mass flow controller

Microprocessor driven digital flow controllers allow one to program, record, and analyze flow rates of various gases with a computer via an RS-485 interface (optional RS-232 is available).

Controllers can be programmed for various control functions including flow set point, totalizer, stop totalizer, read totalizer, totalizer from preset flow, stop at preset total, auto zero, and more. Principles of Operation

Metered gases are divided into two laminar flow paths, one through the primary flow conduit, and the other through a capillary sensor tube. Both flow conduits are designed to ensure laminar flows and therefore the ratio of their flow rates is constant. Two precision temperature sensing windings on the sensor tube are heated, and when flow takes place, gas carries heat from the upstream to the downstream windings. The resultant temperature differential is proportional to the change in resistance of the sensor windings.

Catalogs

DFC

8 Pages

Other Aalborg Instruments products

Mass Flow Meters / Controllers

Related Searches

- Aalborg valve

- Hand valve

- Control valve

- Stainless steel valve

- Water valve

- Threaded valve

- Electrically operated valve

- Regulating valve

- Stop valve

- Gas solenoid valve

- Normally closed solenoid valve

- Biogas valve

- 2-way solenoid valve

- Metal solenoid valve

- Valve for industrial applications

- Nickel-plated brass valve

- Water solenoid valve

- 2-way valve

- Electrically-operated valve

- Pilot-operated solenoid valve

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.