Whether you are a robot programmer or welder, ABB offers you a full range of easy-to-use software tools to help you to improve your arc welding process by increasing productivity, reducing risks and maximizing the return on investment of your robot systems.

Production Manager

Production manager monitors and controls the production cycle, is application independent and can also be used in non-welding applications. Production Manager takes care of:

Describe your parts to produce

Run Setup and Service routines at certain intervals

Map our physical cell layout to logical work areas

Organize program flow in a standardized chain of events, maintaining dynamic execution

Synchronize certain jobs if MultiMove

Initiate the production via PLC or an Operator

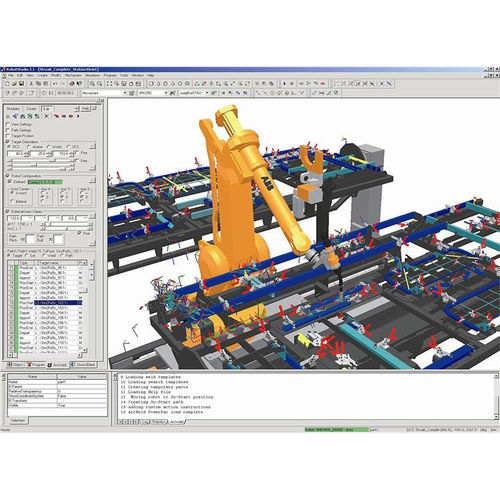

RobotStudio ArcWelding PowerPac

ArcWelding PowerPac (AWPP) is an add-on to RobotStudio, which is a unique, geometry based off-line programming tool for generating arc welding programs.

The programmer defines weld locations on the CAD geometries and the system automatically creates robot positions in relation to that geometry including approach and departure positions.

In other words, it has never been easier to program arc welding robots.

RobotWare Arc

It is a simple yet powerful program since both the positioning of the robot and the process control and monitoring are handled in one instruction. I/O signals, timing sequences and weld error actions can be easily configured to meet the requirements of a specific installation.