- Environment - Health - Safety

- Waste Treatment

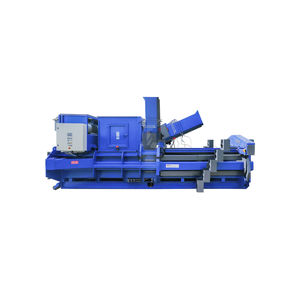

- Horizontal baling press

- abba-Pressen Vertriebs GmbH & Co KG

- Products

- Catalogs

- News & Trends

- Exhibitions

Horizontal baling press Albamat 500 V5channelfor cardboardfor paper

Add to favorites

Compare this product

Characteristics

- Orientation

- horizontal

- Loading

- channel

- Applications

- for cardboard, for paper, for plastics

- Other characteristics

- automatic, compact, mobile

- Compression power

600 kN

- Bale weight

Min.: 450 kg

(992 lb)Max.: 550 kg

(1,213 lb)

Description

60 t pressing force

Suitable for pressing: paper, cardboard, printing waste, foil, hard and soft plastics (PET, HDPE etc), fleece

Low energy consumption due to advantageously crossed press cylinder arrangement (2 press cylinders)

5-fold automatic vertical tying

Ground slide and piston valve for covering the needle opening (prevents contamination of the binding unit with plastic or other small particles, etc.)

Channel adjustment - 3 sides, hydraulic-automatic, 4 working cylinder

4 retaining clamps to retain expanding material in the press channel

Photocell control in the filling chute

Continuous feeding by conveyor belt etc.

Fast cycle times

Additional photocell for overfilling

Mobile, hook lift according to DIN

Pivoting tying unit for transport and service

Simple and safe operation via 5.7" touch panel and push button function

10 programs for different materials (paper, foil, plastic, user recipes etc.)

Operator side freely selectable

Vertical stamp as standard equipment

Optional: Tank and control cabinet heating and vertical stamp

Hopper as required

Catalogs

Albamat 500 V5

2 Pages

Other abba-Pressen Vertriebs GmbH & Co KG products

Channel baling presses

Related Searches

- Baling press

- Vertical chamber baling press

- Cardboard baling press

- Horizontal baling press

- Front-loading baling press

- Paper baling press

- Automatic baling press

- Plastic baling press

- Waste baling press

- Compact baling press

- Channel baling press

- Single-chamber baling press

- Bottle baling press

- Film baling press

- Can baling press

- High-density baling press

- Mobile baling press

- Wood baling press

- Wood chips baling press

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.