- Products

- Catalogs

- News & Trends

- Exhibitions

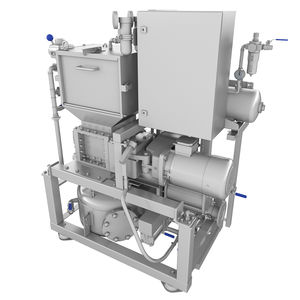

Membrane bioreactor FM 6123for wastewater treatmentmodular

Add to favorites

Compare this product

Characteristics

- Type

- membrane

- Applications

- for wastewater treatment

- Configuration

- modular

Description

With over 40,000 membrane modules installed, ABIONIK is your competent partner for submerged filter modules for all MBR applications.

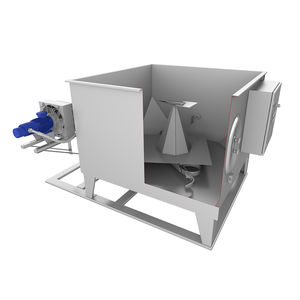

For our customers, we are continuously expanding our product range and investing in the expansion and optimization of our production facilities. The processing of high-grade plastics (PP) and stainless steel components (SS 304, SS 316 optional) guarantees highest quality and a long service life. Further filter sizes can be flexibly configured due to the modular design.

Compared to conventional activated sludge plants, the technology has a number of advantages as a combination of proven activated sludge technology and innovative membrane process. The membrane filters are placed directly in the activated sludge tank or in downstream filtration chambers, where they ensure reliable retention of activated sludge, bacteria and viruses. Therefore, a conventional secondary settling tank is no longer necessary to achieve the highest effluent quality.

low space requirement, compact design, no secondary clarifier required

excellent effluent quality, hygienization of the sewage plant effluent

Reuse of the filtrate, e.g. as process water

robust construction

reliable operation

Material org. polymer, PES

Separation limit ultrafiltration

MWCO 150 kDalton

Pore size (nominal) approx. 35 nm

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.