- Products

- Catalogs

- News & Trends

- Exhibitions

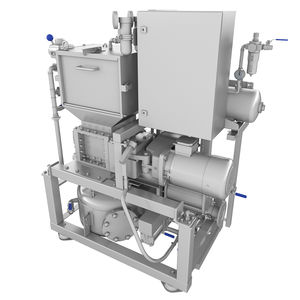

Biological waste water treatment BMA seriescompactcontainerized

Add to favorites

Compare this product

Characteristics

- Options

- biological

- Other characteristics

- compact, containerized

Description

A membrane bioreactor (MBR) is a wastewater treatment process combining membrane filtration with biological treatment. This innovative technology offers several advantages over the conventionally activated sludge process. Among these advantages are higher biomass concentration, eliminating the needs of secondary clarifiers and improved effluent quality.

ABIONIK transforms sewage to clear and high quality water. The small footprint of the treatment technology enables the systems to be integrated in natural, picturesque surroundings and to treat wastewater for irrigation use.

ABIONIK has the core technology inside the MBR which consists of polypropylene plates with a polymeric membrane on each side. The membrane is welded on rigid frame. The module reduces virus and bacteria by 99.9999 %. Filter plates are continuously aerated through bubble diffusers to keep them clean. The membranes don’t need regular chemical cleaning except one or two maintenance clearings per year.

ABIONIK is developing compact package systems for MBR plants so that up to 1000 m3/day can be filtered in one 40-foot ISO container. The inside tanks are made of stainless steel sheets.

fast delivery and start-up due to the mobile concept

german quality equipment in stainless steel housing

compact design

high packing density

effluent with irrigation water qualities (no microorganism, no smell)

very good price-performance ratio

low maintenance and minimum operation requirement

minimum construction work on site and easy to relocate

raw wastewater pump stations

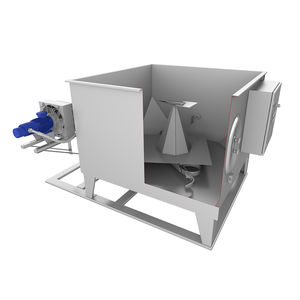

pretreatment

biological treatment systems

membrane filtration unit

permeate storage tank

sludge treatment

odor control system

Related Searches

- Liquid separator filter

- Solid classifier

- Liquids separator

- Water separator filter

- Filtration system

- Liquid filtration system

- Classifier for the recycling industry

- Water purification unit

- Oil separator

- Screen

- Waste water treatment

- Automatic separator

- Activated carbon pre-filter

- Separator filter for the food industry

- Filter for chemical applications

- Filter for the pharmaceutical industry

- Water treatment filter

- Bioreactor

- Biological waste water treatment

- Sewage lifting unit

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.