- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Underwater pelletizer ACSSwater ringair-cooledfor plastics

Add to favorites

Compare this product

Characteristics

- Type

- underwater, water ring, air-cooled

- Applications

- for plastics, for plastic waste, for polystyrene, for EPS

- Sector

- for the chemical industry

- Other characteristics

- compact, belt conveyor, with band filter, for plastic pellet manufacturing

Description

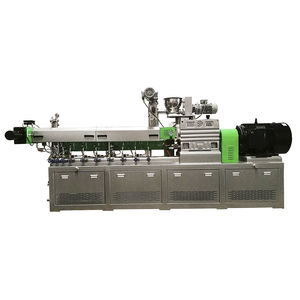

ACSS Double Stage Cutter Compactor Plastic Recycling Pelletizing Line Granulator Machine

The acs series compacting and pelletizing system combines function of crushing, compacting, plasticization and pelletizing to one step.applied in the plastics recycling and pelletizing process.

ACS system is a reliable and efficiency solution for plastics films, raffias, filaments, bags, woven bags and foaming materials re-pelletizing.

Final productions produced by acs system are in the form of pellets/ granules, can directly put into the production line for film blowing, pipe extrusion and plastics injection, etc.

SPECIFICATIONS

Target Recycled Material:HDPE, LDPE, PP, BOPP, CPP, OPP, PA, PC, PS, PU, ABS

Final Product Shape:Particles

System composition:Belt Conveyor, Cutting Compactor, Single Screw Extruder, Filtration, Pelletizer, Water Cooling Device, Dehydration Section,Conveyor Fan, Product Silo.

Output Range:150kg/h-1200kg/h

Feeding Device:Belt Conveyor (Standard), Roll Hauling off device (Optional)

Compactor Volume:300L-1400L

Diameter of screw:80mm-180mm (Standard)

Material of screw:38CrMoAlA (SACM-645), Bimetal (Optional)

L/D of screw:31/1, 32/1, 34/1, 36/1 (According to the characteristics of recycling)

Heater of barrel:Ceramic heater or Far-infrared heater

Cooling of Barrel:Air cooling of fans through blowers

Vacuum deashing exhaust:Two Double-zone vacuum degassing system (Standard)

Pelletizing type:Water-ring pelletizing/ water-strands pelletizing/ Under-water pelletizing

Voltage Standard:According to the Voltage of the Customer's Location

Optioanl device:Metal detector, Roll hualing off device, Masterbatch and additives feeder

VIDEO

Catalogs

No catalogs are available for this product.

See all of Aceretech‘s catalogsRelated Searches

- Crushing plant

- Stationary crushing and screening plant

- Waste shredding machine

- Pelletizer

- Single-shaft shredding machine

- Recycling plant

- Paper shredding machine

- High-capacity crushing plant

- Rotor pelletizer

- Cardboard shredder

- Plastic pelletizer

- Cone crushing and screening plant

- Waste granulator

- Tire shredder

- Compact pelletizer

- Plastic recycling plant

- Crushing recycling line

- Roller crusher

- Granulator for pharmaceutical applications

- Rotary shear shredder

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.