- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

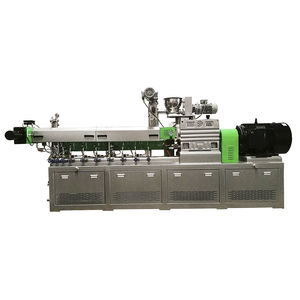

Compounding screw extruder ATErecyclingfor thermoplasticstwin-screw

Add to favorites

Compare this product

Characteristics

- Applications

- compounding, recycling

- Treated material

- for thermoplastics

- Number of screws

- twin-screw

- Output

Max.: 1,500 kg/h

(3,306.9339 lb/h)Min.: 40 kg/h

(88.1849 lb/h)- Screw diameter

Max.: 93 mm

(3.7 in)Min.: 36 mm

(1.4 in)

Description

ATE series parallel twin screw extruder is driven by motor, torque distribution gearbox,processing part, temperature control device, mold part and downstream grain cutting system.

ATE twin screw extruder adopts the principle of modular design and standardized production of components, so as to present stable and reliable performance.

With the principle of modularization, ATE series extruding machines can provide highly

customizable solutions according to customers' process and special requirements. Based on

different output torque levels, there are two types of ATE extruders: basic type and efficiency type.

ATE co-rotating twin screw extrusion machinery combines a variety of cutting systems, such

as water strands cutting system, die surface cutting system and underwater cutting system.

Relay control and PLC control are both used in ATE electrical control system. All key electrical components are European branded to ensure significant stable performance of the control system.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Aceretech‘s catalogsRelated Searches

- Extrusion line

- Thermoplastic extrusion line

- Pelletizer

- Screw extruder

- Twin-screw screw extruder

- Rotor pelletizer

- Pipe extrusion line

- Plastic pelletizer

- Multilayer extrusion line

- PVC extrusion line

- Waste granulator

- Single-screw screw extruder

- Polypropylen extrusion line

- Compact pelletizer

- Polyethylene extrusion line

- Compounding screw extruder

- PP screw extruder

- HDPE extrusion line

- PE screw extruder

- ABS screw extruder

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.