- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

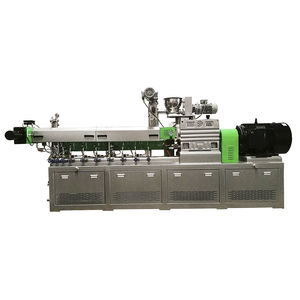

Pelletizing extruder ATE65for PVCfor PPfor PE

Add to favorites

Compare this product

Characteristics

- Applications

- pelletizing

- Treated material

- for PVC, for PP, for PE, for ABS, for PET, for HDPE, for LDPE

- Number of screws

- twin-screw

- Other characteristics

- compact, for masterbatch

Description

ATE65(001) Environmental Protection Granule Machine Manufacturer

Product Description

Aceretech's ATE series of twin-screw extrusion pelletizing machine is used for recycling PET bottle/sheet/film flakes, regular solid polymer flakes, and polymer compounding.

ACERETECH’s advantages:

1. Precise temperature controlling. NO hydrolyzing. NO yellowing.

2. IV reduction less than 0.06 dl/g ( tested based on clean and dried PET flakes)

3. ATE co-rotating twin screw extrusion machinery combines a variety of cutting systems, such as water strands cutting system, die surface cutting system and underwater cutting system.

4. PET pelletizing output capacity: 300kg/h, 500kg/h, 1000kg/h, 1500kg/h, 2500kg/h (tested based on flakes of average size 6mm).

1) Simple design, user-friendly operation.

2) Siemens original motors, ABB/Schneider converts.

3) Celduc solid relay, Gefren pressure sensors, Omron Temperature controllers, LS air switch.

4) Lower investment cost for a high quality and durable machine.

5) Low energy consumption, High output capacity.

6) Usual delivery time: 60 days.

7) Engineers are available to do commissioning work abroad.

Model:ATE65

Dia. of screw(mm):62.4

L/D:32-64

Screw speed Max(rpm):600

Torque per shaft(Nm):675

Specific torqueT/A3:4.8

Output(kg/h):200-400

VIDEO

Catalogs

No catalogs are available for this product.

See all of Aceretech‘s catalogsRelated Searches

- Extrusion line

- Thermoplastic extrusion line

- Pelletizer

- Screw extruder

- Twin-screw screw extruder

- Rotor pelletizer

- Pipe extrusion line

- Plastic pelletizer

- Multilayer extrusion line

- PVC extrusion line

- Waste granulator

- Single-screw screw extruder

- Polypropylen extrusion line

- Compact pelletizer

- Polyethylene extrusion line

- Compounding screw extruder

- PP screw extruder

- HDPE extrusion line

- PE screw extruder

- ABS screw extruder

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.